In spite of technological advances, forestry tasks continues to be one of the most dangerous activities, in particular when workers do not have adequate training (Albizu-Urionabarrenetxea et al, 2013). The most dangerous activity is felling or cutting trees. The three commonest types of fatality are due to being struck by a tree or branch, slips and trips, and cut by the chainsaw (Robb et al, 2014). In fact, the chainsaw can be considered one of the most dangerous work equipment in the field of occupational health and safety (Robb et al, 2014, Enez et al, 2014) with ra-tios in some cases 4 or 5 times higher than other risks in agricultural work (Am-brosio et al, 2001).

Thereby, training is a key element to reduce accidents, especially given that, in Spain, there are vague mandatory specifications about the type of training, content and duration, just according to the direct translation of the EU Framework Directive. Therefore, there are not minimum clear and concrete specifications, of mandatory status, concerning the skills of the operators of such equipment should be acquired on safety and health, as other dangerous equipment such as removable tower cranes, mobile cranes or various activities in the construction, metal indus-try, etc.

In this context, a new European project was launched in September 2014 (VET-Safety project) , with the aim to develop a new common standards such as the use of chainsaws and working at heights within the broader skills sectors of forestry, agriculture and the environment. Previously to reach the cited objective, it is nec-essary to analyze all available information (accident data, literature, and workers knowledge) in order to know accurately the state of occupational training in Spain and other countries. Then, future standards will be defined based on the obtained results.

Objectives

The main aims of current study are the following:

- A review of contents normally included in the Spanish educational materials such as guides, guidelines, manuals and documents aimed or likely to be used as support in the training of workers using the chainsaw as work equipment.

- Characterization of workers injured by chainsaw.

- Development a tool needed to assess the weaknesses in the training received by the workers subject of the investigation.

Following the objectives of the previous section, activities in this study can be classified as follows: literature review, accidents analysis and design and devel-opment of a questionnaire as a tool for evaluating the workers occupational train-ing.

1 Guides, manuals and document about chainsaw review

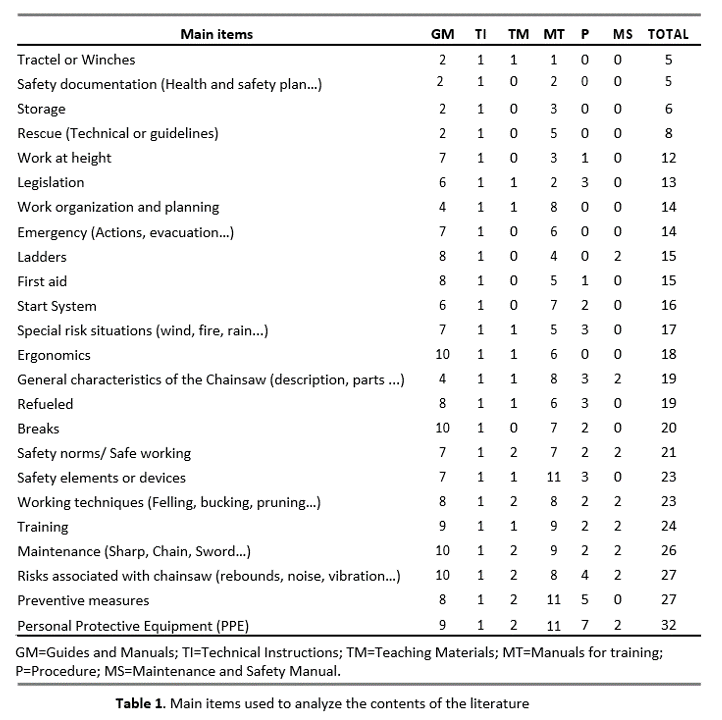

A total of 34 Spanish documents were analyzed. These are classified into six different categories according to its size and origin: Guides and Manuals (GM) (Edit-ed by Public Organisms or Administration), Technical Instructions (TI) (work instructions in management systems), Teaching Materials (TM) (presentations), Manuals for training (MT) (oriented to student), Procedure (P) (short extension) and Maintenance & Safety Manual (MS) (edited by manufacturers).

In order to facilitate bibliography analysis, a list of contents was designed using as main references European Chainsaw Certificate and Professional Qualifications of the Ministry of Employment. The checklist was developed with a total of 43 items, 24 were main items and 19 were subcategories of the main items. Later, the contents of each document were analyzed and the existence of the different items was verified and registered.

2 Accidents analysis

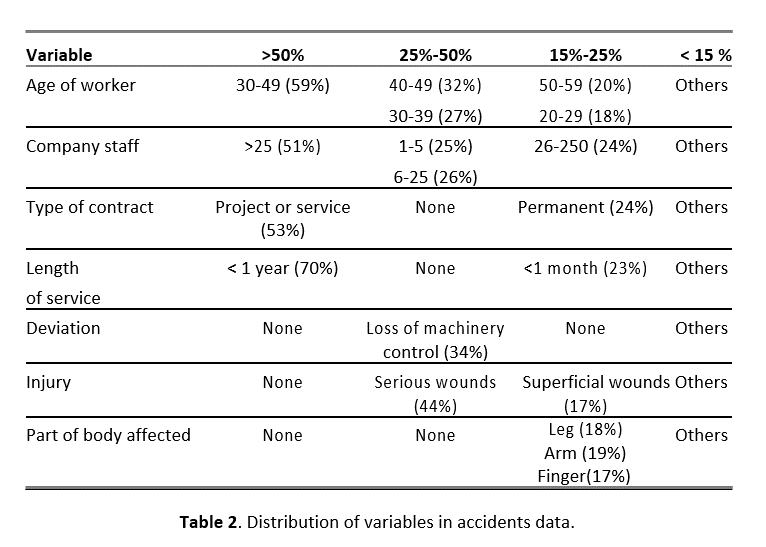

All 274 occupational accidents ocurred from 2009 to 2013, linked to the use of chainsaw occurred in Andalusia and officially recorded were supplied by Anda-lusian Goverment and studied.These Accidents were notified using the Official Workplace Incident Notification Form. A descriptive analysis of all accident vari-ables included in the Official Form using SPSS 22 was developed. Main variables were selected, according to their relevance in literature about characterization of occupational accidents, and the importance of the result obtained.

3 Development of a questionnaire

The research tool which was chosen to achieve the third objective of this study was the questionnaire.

In a first approach, a preliminary version of the questionnaire was designed integrating the previous section results. Thereby, the gaps detected in the Guide, manuals and documents about chainsaw review and the injured worker profile defined in the analysis of accidents were used as sources of information as well as the prevention observations form and the sample survey given by Albizu Urionabarrenetxea (2012). Also, it had considerated European Chainsaw Certificate and Professional Qualifications of the Ministry of Employment, above mentioned.

In a second step, the preliminary questionnaire was assessed by expert judgment. Individual Aggregate Method proposed by Corral (2009) was used to review the questionnaire. Five experts were selected, two more than the minimum required. They used the evaluation form model proposed by Corral (2009) and previously adapted. The model assessed, on one hand, general aspects of the questionnaire and, on the other hand, clarity, coherence, language and bias of each items.

Finally, the necessary changes resulting from the evaluation were carried on and a final version of the questionnaire was obtained.

Similarly to the previous section, the results are showed according to the three ini-tial objectives.

1 Guides, manuals and document about chainsaw review

The results of the analysis of the available literature focuses on the use of chain-saw workers is presented in Table 1.

The content that appeared most frequently was “personal protective equipment”, which was present in all documents except two guides. In second place, the most cited were “preventive measures” and, in the third place, “risks” and “maintenance” obtained the same citation. Among the risks, noise and vibration were the most mentioned and rebounding and pulls the least mentioned. In terms of maintaining, the chain was the most mentioned and the lubrication the least mentioned.

Note that the procedure document, developed by a city council as part of its management system, has been included because it is the only document that includes all the content, so it is the most complete. Also, the least cited contents were “tract el or winches” and “safety documents”, which appeared only in three documents. In second and third place, the less cited were “storage” and “rescue”. “Working at height” also had a bad position, being the fourth less mentioned. Within this work, rarely work positioning system (har-ness, rope, anchoring devices...) were mentioned.

2 Accidents analysis

In order to better understanding causes of accidents associated with chainsaw, a sample of 274 occupational accidents were analyzed. After a frequency analysis performed using SPSS 22, the main results were summarized in Table 1. In first column were included results with percentages bigger than 50%. It can be observed that workers between 30-49 years, represented 59% of accidents studied, then this group of workers were included in the first column. In second column were included groups of results between 26-50%, in the third column results between 15-25%, in the last column were included remaining results with a representation lower than 15%.

Results showed that the most common accidents profile linked to the use of chainsaw is a worker male, because not female accidents were found in the accidents studied, between 30-49 years old, in a company with more than 25 workers, em-ployed for a specific project or service, with a length of service less than 1 year, caused as consequence of loss of machinery control, with consequences of serious wounds in legs, arms, or fingers. Results obtained were aligned with previous results obtained by Robb and Cocking (2014). Cited authors highlighted inexperience as a very important factor in chainsaw accidents. Similarly they pointed arms, and legs as the most affected body parts when a chainsaw accident occurs.

3 Development of a questionnaire

In order to design a tool to assess the weaknesses in the training received by workers who use chainsaw, a questionnaire was designed and reviewed by experts.

In a first stage, a preliminary questionnaire was obtained based on all literature and information sources available, referenced in the methodology. This question-naire was composed of 60 items.

In a second stage, Individual Aggregate Method was applied and the evaluation forms were processed. According to the experts, the most important conclusion was that the number of items was excessive and sometimes the language was difficult considering the education level of the workers.

For that reason, following the observations of the experts for each item, the questionnaire was modified. The result was a new questionnaire with 25 items which was sent back to the experts. After a second review, the questionnaire was accepted by them.

Identified gaps emphasizes that there are deficiencies in the available guides, manuals and document about chainsaw. Very important contents such as “working at height”, “rescue” and “safety documentation” were among the least mentioned.

However, they are areas that can be a source of risk and the lack of knowledge of workers about them could cause accidents. Therefore, it is important to include these contents in the minimum obligatory competencies for workers.

Furthermore, the characterization of the most frequent accidents can be very useful in order to improve the occupational health & safety management and adapt the minimum obligatory competencies to the injure worker profile defined, especially for temporary workers without previous experience. They must be considered in the development of users manuals and OHS training courses, as well.

Discovered gaps and injured worker profile defined added to the analysis of other studies about chainsaw have provided a valuable tool for research: a questionnaire. This questionnaire will be able to be used, in future studies, to evaluate deficiencies in the workers training process. In this way, there has been a first step towards the identification of mandatory minimum competences for workers with chain-saws.

Authors would like to acknowledge the contributions to this research from: Proyecto Erasmus+,"Vocational Education & Training Standards in Agriculture, Forestry & Environmental Safety at Heights: VET-SAFETY", Junta de Andalucía, Diputación de Málaga and Agencia de Medio Ambiente y Agua de Andalucía.

Ambrosio Torrijos, Y., Tolosana Esteban, E., Vignote Peña, S., & Garasa, M. (2001). Analysis of occupational health and safety in forest harvesting and thinning in Spain. Chapingo Jour-nal, 7, 55–65.

Albizu-Urionabarrenetxea, P., Tolosana-Esteban, E., & Roman-Jordan, E. (2013). Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. Forest Systems, 22(3), 392-400.

Albizu Urionabarrenetxea, P. (2012). Diagnóstico de la seguridad en los aprovechamientos fores-tales a partir de registros empresariales, bases de datos oficiales y muestreos de campo: pro-puestas de actuación (Doctoral di ssertation, ETSI Montes, UPM).

Corral, Y. (2009). Validez y confiabilidad de los instrumentos de investigación para la recolec-ción de datos. Universidad de Carabobo. Revist a Ciencias de la Educación. Segunda Etapa. Año 2009.Vol 19. Nº 33, 228-247.

Enez, K., Topbas, M., & Acar, H. H. (2014). An evaluation of the occupational accidents among logging workers within the boundaries of Trabzon Forestry Directorate, Turkey. International Journal of Industrial Ergonomics, 44(5), 621-628.

European Chainsaw Certificate. (2014). Carnet Europeo de Motoserrista. ECS1: Mantenimiento de la motosierra y técnicas de tronzado.

European Chainsaw Certificate. (2014). Carnet Europeo de Motoserrista. ECS2: Técnicas básicas de tala de árboles (árboles pequeños).

European Chainsaw Certificate. (2014). Carnet Europeo de Motoserrista. . ECS3: Técnicas avan-zadas de tala de árboles (árboles medianos y grandes).

European Chainsaw Certificate. (2015). European Chainsaw Standars. ECS4: Windblow & Damaged Tree Techniques.

Pérez de la Raya, g. (2001). Guía para la adecuación y evaluación de riesgos en las explotaciones forestales. Instituto Navarro de Salud Laboral, Pamplona, Spain.

Real Decreto 108/2008, de 1 de febrero, por el que se complementa el Catálogo nacional de cua-lificaciones profesionales, mediante el establecimiento de ocho cualificaciones profesionales de la Familia profesional agraria.

Robb, W., & Cocking, J. (2014). Review of European chainsaw fatalities, accidents and trends. Arboricultural Journal: The International Journal of Urban Forestry, 36(2), 103-126.

Papers relacionados