Avilés González, Cristina

Mining engineering, metallurgic and material’s science department. University of the Basque Country.

Colina de Beurko s/n 48901 Barakaldo, Vizcaya, Spain.

34 629723833 / iipavgoc@lg.ehu.es

Sánchez Conejo, Alfonso

Mining engineering, metallurgic and material’s science department. University of the Basque Country.

Colina de Beurko s/n 48901 Barakaldo, Vizcaya, Spain.

34 946 014 995 / iipsacoa@lg.ehu.es

ABSTRACT

During the year 2002, the J.M.Madariaga Official Laboratory make several technical inspections about safety and occupational risk prevention in all Spain. In the Foral Community of Navarra, several technical inspections were done in opencast mines. The working’s methods of these quarries are substantially differents, as there are quarries of agglomerates, magnesitea, etc., where the machinery and equipments are also differents. Also, the exploitation conditions of the quarries of The Foral Community of Navarra are strongly differents in comparison with other Communities of the North of Spain. Due to the special features of the extractive industry, an exhaustive check list and a strict methodology were designed to valuate safety conditions in each work’s place, being in mobile or in fix equipment, as well as the working methods used. We used The Spanish Occupational Risk Prevention Law 31/1995, as well as the Royal Order 1215/1997 which establish minimum conditions of health and safety for the use of the work’s equipments and the Royal Order 1389/1997 which establish minimum dispositions to protect health and safety of workers in the mining industry and finally The General Code of Basics orders for mining safety

From the beginning of the study it appears as an efficient tool for point out deficiencies and faults, which in few occasions due to the serious risks it carries, must be corrected inmediately.

Once finished the study, it has served as a referencial document for an objective knowledge of the safety of Mining industry and for design a lot of correction actions or optimizing methods in the studied quarries.

Palabras clave

Mining, safety inspections, correction actions, Foral Community Navarra.

INTRODUCTION

The Spanish Economy Ministry, through the State of Energy and Mining Office, are very interested in the knowledge of the safety conditions of Mining activity, in a way to improve the safety and prevent occupational risks in an activity with a high degree of sinisters.

The J.M. Madariaga Official Laboratory (L.O.M.) took the responsibility of inspect a representative number of mining companies of all the country. The selected mining companies has different types of exploitation methods: underground mines, and opencast mines; the exploited raw materials are also differents: coal, Pb-Zn, salt, uranium, aggregates, sands, ornamental rocks, etc.

In the Foral Community of Navarra the Madariaga Official Laboratory inspected 2 opencast mines. The Foral Community of Navarra is located in the North-east of Spain, and there are 60 mining exploitations all of them opencast mines

The main raw material is limestone used for construction industry, public works, siderurgy, cement industry and concrete manufacturing. Other importants raw materials are ornamental rocks, clay and magnesite.

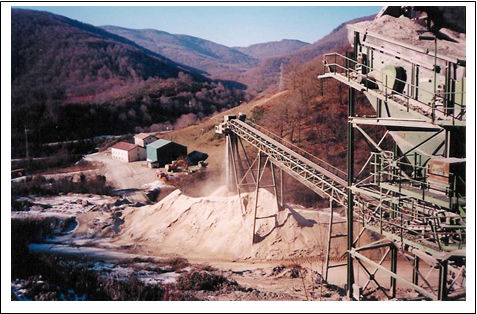

The landscape of the Foral Community of Navarra is very abrupt with high mountains and deep valleys, and the quarries are located in regions with strong slopes, which determines the working methods. (Photo n.1) By the way, the climate is template and wet with common precipitations, which also affects worker’s safety.

Photo nº 1

The average of workers by quarry is 10 persons; this low worker’s number imply a high degree of work duty and an absence of specialization.

The inspections were made in one quarry of limestone and in one open pit mine of magnesite. In both of them exists special characteristics which make them relevants between the rest of the mining exploitations of the Foral Community of Navarra: the limestone quarry has an unique working slope of 100 metres high (the Spanish mining legislation only permits, in general, slops of less than 20 metres high). (Photo n.2) The open pit mine of magnesite is the biggest open pit mine of this characteristics of the North of Spain and is located in The Pirineos which is a region of a high landscape value.

METHOD

Previously to the beginning of the inspections, the more detailed information possible about the quarries was searched, with the help of the members of the Foral Navarra Government, through the Department of Industry and Technology, Trade and Employment.

The check list is the most important document of the study and was carefully designed in order to obtain the best information about the safety and occupational risk of each quarry. Therefore we used the following orders:

- The Spanish Occupational Risk Prevention Law 31/1995.

- The Spanish Law 54/2003 which modifies the normative of The Occupational Risk Prevention Law.

- The Royal Order 1215/1997 which establish minimum conditions of health and safety for the use of the work’s equipments.

- The Royal Order 1389/1997 which establish minimum dispositions to protect health and safety of workers in the mining industry.

- The General Code of Basics orders for mining safety.

- The Supplementary Technical Instructions for opencast exploitations.

The principal sections of the check list includes the following aspects:

- 1. Safety and health documentation.

- 2. Working methods.

- 3. Organization and worker’s duty.

- 4. Circulation areas and worker’s spaces.

- 5. Illumination.

- 6. Hygienic installations.

- 7. Gas supply.

- 8. Safety signposting and personal protection equipments.

- 9. Switch on elements.

- 10. Electric installations and equipments.

- 11. Tools and equipment maintenance.

- 12. Mobile equipment.

Also, an extensive graphical report of each exploitation was obtained to point out the deficiencies and observed faults.

CONCLUSIONS

The following reflexions must be taken into account:

- 1. Is remarkable the obvious differences depending on the size of the mining company; in this way, in the magnesite open pit mine which has a high worker’s number and great economic resources, the working organization, safety training and equipments are adequated.

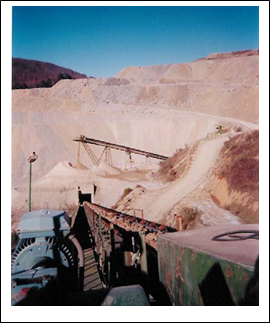

- 2. Due to topographic causes and to a wrong exploitation design, tracks have great inclination and insufficient width. In this conditions, the transport of extracted material is done by allowing it to turn upside down the slope, causing related risks.

- 3. Frequently the installations are obsoletes, causing a lot of noise and dusty atmosphere, without dust and noise prevention systems.

According to the sections of the check list used in the inspections, the following deficiencies are detected:

- 1. Safety and health documentation. One of the inspected mining activities has no internal safety procedures, risk evaluation and neither emergency plan. Also, has no safety training plans.

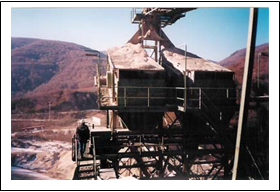

- 2. Working methods. In one case, the exploitation design is so wrong that only exists an unique working slope of 100 metres high: the Spanish mining legislation stablish the working slops in less than 20 metres high; only under special conditions, slopes of more than 20 metres are permitted, because it will implies a lot of serious risk in the working methods. (Photo n.3) The design of access and tracks is, in occasions, not adequated. Existence of movement of materials by turn upside down the slope. (Photo n.4)

- 3. Organization and worker’s duty. Generally this is not a deficient section.

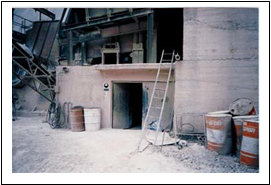

- 4. Circulation areas and worker’s spaces. In both mines, exists dusty atmospheres and a high noise degree; also the transit areas are irregulars and dirty. Absence of handrails and deficient stairs. Absence of mobile element’s protectings. (Photos n.5,6 and 7)

- 5. Illumination. Commonly don’t exists emergency ligths, neither intense ilumination where is needed.

- 6. Hygienic installations. Insufficient installations.

- 7. Gas supply. No signposting and inexistence of fire protections.

- 8. Safety signposting and use of personal protection equipments. Absence of complete signposting and low use of personal protection equipments.

- 9. Switch on elements. Commonly, inexistence of emergency stops in conveyor belts.

- 10. Ellectric installations and equipments. Deficient electric isolation and absence of safety protocol in transformers.

- 11. Tools and equipment maitenance. Absence of equipment certification, neither registration of maintenances.

- 12. Mobile equipment.

In some cases the vehicles, excavators and drilling machines have no protection systems against rolling over or falling objects. (Photo n.8)

Photo nº 2 Photo nº 3

Photo n. 4 Photo n. 5

Photo nº 6

Photo n. 7 Photo n. 8

Papers relacionados