Castañon, José

Núcleo de Ergonomia e Segurança do Trabalho [Nucleus of Ergonomics and Safety at Work]/Universidade Federal de Juiz de Fora [Federal University of Juiz de Fora]/Faculdade de Engenharia/Universidade Federal de Juiz de Fora/Juiz de Fora – MG – Brasil 55 32 3229 3405/ nest@ergonomia.ufjf.br

Dilly, Geraldo

Núcleo de Ergonomia e Segurança do Trabalho [Nucleus of Ergonomics and Safety at Work]/Universidade Federal de Juiz de Fora [Federal University of Juiz de Fora]gld@acessa.comCarvalho, MeristelaNúcleo de Ergonomia e Segurança do Trabalho [Nucleus of Ergonomics and Safety at Work]/Universidade Federal de Juiz de Fora [Federal University of Juiz de Fora]meristelacarvalho@yahoo.com.br

Fonseca, Juliane

Núcleo de Ergonomia e Segurança do Trabalho [Nucleus of Ergonomics and Safety at Work]/Universidade Federal de Juiz de Fora [Federal University of Juiz de Fora]julianearq@uol.com.br

Ramalho, Priscila

Núcleo de Ergonomia e Segurança do Trabalho [Nucleus of Ergonomics and Safety at Work]/Universidade Federal de Juiz de Fora [Federal University of Juiz de Fora]pramalho@powermail.com.br

Ribeiro, Elvira

Núcleo de Ergonomia e Segurança do Trabalho [Nucleus of Ergonomics and Safety at Work] / Universidade Federal de Juiz de Fora [Federal University of Juiz de Fora]elarant@terra.com.br

ABSTRACT

The aim of this paper is to present the results obtained from the application of the methodology of Ergonomizing Intervention in the work positions of the dairy products sector of a supermarket.

Key words

Ergonomics, workplace, dairy products sector.

INTRODUCTION

The elaboration of the design project for workplaces and work stations is a particularly difficult function, since anticipating the best conditions for the workers’ well-being is a very relative matter. Iida [1] regards the analysis of work positions as the study of part of the system where a worker operates. The ergonomic approach to the level of the work position analyses the task, the posture and the movements of the worker and their physical and psychological demands.

METHODS AND TECHNIQUES

To carry out Ergonomic Analysis in the dairy products sector of a supermarket we used the Ergonomizing Intervention methodology of Moraes and Mont’Alvão [2], which is composed of 4 stages: Ergonomic Analysis, Ergonomic Diagnosis, Ergonomic Planning, and Ergonomic Evaluation and Validation. In this study, the first three stages of this methodology were carried out.

Ergonomic Analysis is an exploratory phase in which the ergonomic problems of the firm are mapped out. At this time, non-systematic observations are carried out in the workplace and non-structured interviews are held with supervisors and workers.

Ergonomic Diagnosis enables a more in-depth study of the problems to which priority has been given and a test of predictions. This is when systematic observations of the task activities, and records of behavior, in a real work situation, are made. Video recordings are made, structured interviews carried out, and questionnaires applied. This stage is brought to a close with the Ergonomic Diagnosis itself, which gives ergonomic recommendations in terms of environment, disposition and configuration of work posts.

Ergonomic Planning uses ergonomic design to deal with the adaptation of work stations, equipment and tools to the physical, psychic and cognitive characteristics of the worker.

DESCRIPTION OF THE OBJECT OF THIS STUDY

The Ergonomizing Intervention was carried out in the work posts of the Dairy products Sector of a supermarket. The population observed was made up of the 4 employees of this sector, all of them men.

The following figure shows the work posts in the Dairy Products Sector focused on in this analysis

Figure 1 - Identification of the work areas focused on in the Ergonomic Analysis

|

The ProblemThe work in the Dairy Products Sector – the target system – involves severe postural discomfort for the operator. In this sector, the operator constantly lifts, handles, carries and transports a large quantity of closed boxes of products from one work area to another. To carry out this task the operator, amongst other postures adopted, bends the lumbar area of the spine at the same time twisting his torso, which causes painful disorders of the spinal column. In the products preparation area, where the products are sliced, wrapped and weighed, the operator remains for a long time in a static position – with the torso upright and his neck bent at an angle of more than 30 degrees, and carries out repetitive prone-supination movements, which can cause muscle fatigue, neck and lumbar pains and tendinitis in the upper limbs. Stage 1: Ergonomic AnalysisEstablishment of the problems and allocation of priority of problems in the man-task- machine system Through non-systematic observation it was possible to detect the problems thatexist in the Dairy Products Sector. With the aim of approaching the situation as a whole and deciding which problems to focus on in the ergonomic diagnosis, we applied a prioritizing technique called GUT (Gravity, Urgency, Tendency)1. |

|

Value |

Gravity |

Urgency |

Tendency |

G x U x T |

|

5 |

The harm and/or difficulties are extremely grave. |

Immediate action is necessary. |

If nothing is done the situation will rapidly get worse. |

125 |

|

4 |

Very grave. |

Some urgency. |

Will get worse shortly. |

64 |

|

3 |

Grave |

As soon as possible |

Will get worse in the medium term. |

27 |

|

2 |

Not very grave |

Can wait for a while. |

Will get worse, but in the long term. |

8 |

|

1 |

Not grave |

There is no hurry |

Will not get worse, and may even get better. |

1 |

With this technique it was possible to establish an order of the most

1 A technique proposed by Kepner and Tregoe, with the aim of ordering the problems identified and prioritizing the steps to be taken.

problematic work areas within the Dairy products Sector:

1st Product Preparation

2nd Storage Area: Cold Store1 and 23rd Storage Area: Storeroom

Table 1 – Ordering of work areas in the Dairy Products Sector

We show below, as an illustration, just two of the problems found in the Dairy Products Sector.

Product Preparation Area

|

PROBLEM |

DESCRIPTION |

|

INTERFACIAL |

To carry out the product preparation activities (slicing, wrapping and weighing), the employee remains with his torso in a static position and bends his neck at an angle of over 30 degrees. Results: * Fatigue of the paravertebral lumbar muscles* Pain in the lumbar region and legs (lumbo-sciatic pain)* Fatigue of the cervical muscles

* Removal of the employee |

Storage area: Storeroom

|

PROBLEM |

DESCRIPTION |

|

MOVEMENT AND INTERFACIAL |

To organize the boxes of milk in the store, the employee carries out repeated movements, lifting and lowering the boxes to take them out of the trolley and put them on the pile. In this activity the employee is constantly bending and rotating his torso. Results:

|

Predictions

Predictions are fundamental for Ergonomic Diagnosis. It is here that the interpretation of the causes of the problems is given so that they can be investigated in the next stage.

Thus in the next stage the following situations should be observed systematically:

• In the product preparation area:

- How long the employee remains in a static position while the products are prepared, and the frequency of repeated movements;

- The height of the work surface for the different users of the work area and whether the space in this area is enough to be able to carry out the task well.

• In the Cold Store area:

- the uncomfortable postures of the employees in the movement and manual transportation of loads;

- the need to reorganize the internal space of the cold stores, paying attention to the height of the shelves;

• In the storeroom:

- the need to adjust the height of the transport equipment and the places where boxes of products are stored;

• In the Sales Area:

- the uncomfortable postures of the employees in the movement and manual transportation of loads and the need to adjust the height of the transport equipment;

Stage 2: Ergonomic Diagnosis

This is the stage at which we get to know in depth and in detail the tasks carried out:

Behaviour records and results

The behaviour records were elaborated from systematic observations, video recordings and photographs of the employees in the Dairy Products sector. At this stage several visits were made, covering all the shifts (morning, afternoon, night).

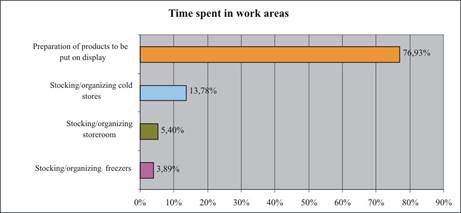

The results of these records generated the following graphs, enabling us to understand and compare the data:

Graph 1 – Time spent in work areas

As can be seen in the graph, the operators remain most of the time in the product preparation area, which reinforces the need to carry out improvements in the work conditions of this area.

A Length of Time Record was made to obtain the length of time and frequency of the postures assumed by each segment of the operator’s body. From these records we can see that the most common posture for the torso was the upright one (static), since the operator spent most of the time during his shift in the Product Preparation Area. As regards the upper limbs, the most common posture was the bent one, and for the lower limbs, the most common was stretched out together.

Analysis of postures

The tasks carried out in the Dairy Products Sector demand of the operator constant moving and manual transportation of loads. Therefore the methods used in the analysis of the postures were LEST/Guélaud (proposed by the Laboratoire de Economie et Sociologie du Travail – Guélaud, 1975) and the LLI – Load Lifting Index - developed by the National Institute for Occupational Safety and Health. For the static activity of product preparation the RULA (Rapid Upper Limb Assessment) method was used.

Results of the LEST / Guélaud method

According to the assessment of physical wear and of global physical wear at work – the task carried out by the employees of the Dairy Products Sector is assessed as a HIGH degree of physical activity (energy spent 1350

Papers relacionados