Hojo, Tetsuo

Institute of Technologists / 333 Maeya / Gyoda / Saitama 361-0038, JAPAN+81 48 564 3851 / hojo@iot.ac.jp

ABSTRACT

In this research, firstly past accident prevention system from Heinrich’s era are reviewed. It is pointed out that it becomes necessary for safety management to analyze an induction factor thought about as a background of an error. Taking as examples of measures on human factors analysis, ideas of the "SHEL model" by Hawkins and the "Swiss cheese model" by Reason are discussed. Next, feature of the accident of the construction industry was analyzed. An approach for a new safety management system in the construction field is described.

Keywords

Safety management, industrial safety, human factors, construction accident

INTRODUCTION

The number of casualty and fatal accident of all industries decreases rapidly from the beginning of 1970's when Occupational Safety and Health Law was enforced to the beginning of 1980's in Japan. The number of industrial accidents of the construction industry changed similarly, but it has the highest labor accident rate among all industries still now. It becomes a very important to study countermeasures for accident prevention.

The construction industry has feature where systematization or making a manual is difficult, because contents of a work and a work condition are not constant. Therefore, the industrial accident generated in construction field has very many things resulting from un-safe action, and various researches have been performed from the viewpoint of human error prevention up to now. The measure paid its attention to the factor that lurks the action on the worker side, as well as on the technical sides, is needed in the safety management. The construction industry is labor concentration type, and when considering a future safety control, an analysis of human factors side becomes very important.

The safety problem study group in the Japan Society of Civil Engineers is doing an investigation concerning safety management system in the construction industry. This problem has been being researched while analyzing "Heinrich Revisited: Truisms or Myths”, written by Fred Manuele. The interesting opinion that Manuele investigated was expressed in it, and the member of the research subcommittee examined the text about Heinrich's research details through this. This investigation research on the safety management system was performed through the examination.

This paper firstly takes a general view of Heinrich's research, and then it introduces ideas of safety management. Next, results of investigating technique of human factors are described. Finally, an approach for safety management is described, after analyzing the current state of the safety management surrounding construction industry.

1.RESEACH ON THE HEINRICH’ S PREMISES

Heinrich (1881-1962) published the book titled "Industrial Accident Prevention" in 1931. In the book, relatinship between industrial injuries and accident causes was analyzed, and so-called Heinrich's premises was led. The essence of the prevention of disaster is retouched in the second edition in 1941, and the accident sequence based on the principle of the industrial safety and the domino theory was expressed.

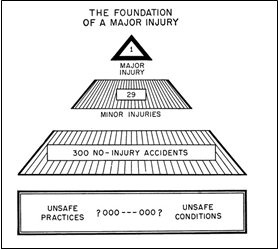

In the field of industrial safety, "Heinrich's premises (triangle)" (Fig.1) is well known to many safety managers. This means rule of thumb with "In the background

of one major accident, there is another 29minor injuries, and, in addition, the same kind of 300 no-injury accident is accompanied". It is suggested to have to consider measures noting a lot of factors that lurk in the back to prevent a serious accident. This is an idea that Heinrich derived from the disaster case in the 1920's. It is recorded that this ratio can be applied to an average case in the note.

According to the Heinrich's analysis, 88% of the direct factor of the accident iscaused by the person's unsafe practice, 10% by mechanical or physical unsafe condition, and 2% of the remainder could not be

Fig.1 Heinrich's triangleprevented. Therefore, it was judged that 98% of the cause of the accident was able to be prevented if the cause of an unsafe practice and an unsafe state was removed. In a word, a lot of unsafe practices and unsafe states exist in the background of such a minor injury (near miss), and it is mentioned that the disaster doesn't occur if an unsafe practices and the unsafe states are eliminate.

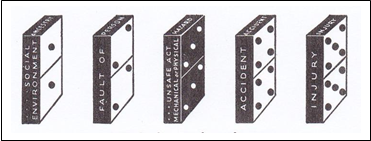

Moreover, it explained the mechanism of the disaster generation by the domino theory (Fig.2). This figure shows that unsafe practices and unsafe states are originated by an individual fault based on social or a domestic defect, as a result, accidents and injuries are

generated. Therefore, it is assumed that it is a point of the

Fig.2 The five factors in the accident sequenceprevention of disaster to remove unsafe practices and unsafe states.

Heinrich's idea carried out this book is in the point that the worker's unsafe practice is the main cause of the accident, and it is a fundamental of the disaster prevention measures to remove the trouble. This idea became a basis of the safety management. This basis for thinking of this Heinrich's safety management has been esteemed as a useful idea for the industrial accident prevention of the industrial field over many years.

2.IDEAS OF SAFETY MANAGEMENT

As industrial structure was remarkably changed from 70 years ago when Heinrich's "Industrial accident prevention" had been written, it has come to bere-examined to the opinion focused the behavior of worker's side. Fred Manuele is describing the necessity of the re-examination from a present aspect about Heinrich's idea in his book, "On the Practice of Safety". First of all, Heinrich's research is the one having derived it from the case study in the 1920's. There is a problem in the reliability of basic data, and a doubt in the point that the change is seen in the content of the description whenever the revised edition is put out.

It is pointed out that the big problems are in the accident cause theory composed of the basis of Heinrich's concept, and should do fundamental reviews to this concept. In a word, it is described that a fundamental review of the theory of "88:10:2" is necessary. For instance, Ted Ferry pointed out in the book, "Modern Accident Investigation and Analysis", published in 1981, as follows; the cause of an un-safe action is often in the factor that exists inside the work systems of working method and working environment. Moreover, it is pointed out by Edwards Deming, famous in quality control field, that the idea of "Principle of 85:15" in the quality control field can be applied also to the safety management; 85% of the problems caused by the work is a responsibility of management in the system, and remaining 15% is worker's responsibility. Therefore, it is described that it is important to investigate the foundation factor related to the entire system, and to improve the management system itself. Alphonse Chapanis, a pioneer in the field of industrial design, also showed the opinion that an investigation of cause of the error is a first step of an accident cause analysis, as well as Deming pointed out. Thus, the research that gives priority to not the worker but the work system has come to be advanced by a lot of researchers.

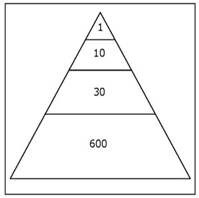

Ferry also described that it should not be stick so much to the component ratio of "1:29:300" of "Heinrich's premises". This component ratio became too popular; as aresult, he had misgiving about misusing only the numerical value. As the reason, it is pointed out that

the reliability of the data derived from statistics of aninsurance company at that time is low. Afterwards, various researches were carried out about this ratio. For instance, Frank Bird analyzed about 1.75 million cases reported from a variety of industrial and commercial industries, and showed the ratio of "1:10:30:600". This is an opinion assumed for 10 minor injuries, 30 minor property damages, and 600 near miss incidents to exist for one serious accident. Therefore, the ratio changes with the times, and it is not eternal from a more scientific viewpoint,

considering statistic's having always changed.

Fig.3 Bird’s triangle

3.ANALYSIS OF HUMAN FACTORS

It came to be done to catch and to analyze all factors thought about as a background of a human error in around 1980. That is, it is an idea of widely analyzing various factors such as not only a factor at an individual level but also the organizations and systems of management as human factors.

As for the definition of the human factors, it seems to be different by research objects such as aviation field and nuclear energy field. In the general industry field, it hasbeen interpreted as "all human factors in which equipment or systems are necessary in order to achieve the set-up purpose"; the problem concerning all the classes andprocesses that human beings, such as those who are engaged in the work of the site,those who take charge of a plan or a design, an administrator who superintends them, a business administrator, and a person in charge of administration, is contained in human factors of a wide sense. Therefore, it is necessary to only analyze broadly the influence affect human action from viewpoints, such as a factor of not only factors of an individuallevel but a group organization level and a social culture level, and to take a measure. There was a tendency to pay attention only to an external direct cause, it is important to grasp clearly human factors as an origin-factor in each process in the background.

In various fields, such as aviation industry, electric power industry, and chemistry industry, investigation research on human factors has been done since before. In aviation industry, it is pointed out that many aircraft accidents resulting from the operation crew have occurred, as the performance of the machine improved. Then, the approach ofmeasures to give priority to human factors is promoted internationally. Educational training of the research based on cognitive science or information processing theory, cockpit resource management training, and incident report system etc. is aimed to improve safety measures with a start.

In electric power industry, the necessity of human factors research in the safety management of nuclear power was strongly recognized with the nuclear plant accident that occurred in 1979. In spite of having taken the multiplex protection measure in which double safety measures were given in huge technical systems, such as power plant, the cause of an accident has many things resulting from human factors. In Japan, in the Human Factors Research Center established in the Central Research Institute of Electric Power Industry, the past fatal accident example is analyzed, a potential factor in back is extracted with a direct cause. And it is striving for recurrence prevention and before-it-happens prevention through development of the human error analysis evaluation technique.

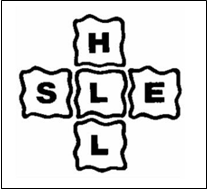

The element of human factors is variously analyzed. As one example, the SHEL model consisting of four elements, proposed by Hawkins, is shown in the Fig.4. The SHEL model is a conceptual model that attempts to indicate the interactions between “man-machine-environment”. The elements of human factors are; Liveware at the center (human), Software (rules and regulations), Hardware (tool and equipment), Environment (working condition) and L at the lower (people around). It is considered that a mismatch between the centre Liveware and any other four components always leads to a source of human error. To prevent a human error, it is needed that the

correspondence of L at the center and surrounding SHEL be always kept proper. Therefore, the relation is requested to be adjusted best so as not to cause the space of each element.

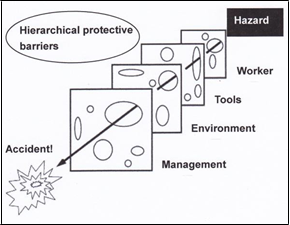

Anothoer example handling with measures by human factors side is the "Swiss cheese model" by Reason, shown in Fig.5. This tries to catch the cause of the accident from an organization side; in many cases, the organization is related to man's decision making for designing, producing, operating and managing in a complex system like present. It is an idea assumed for being few that an accident occurs by a single cause, and a potential hazard could penetrate through many protective walls.

Organizations develop several layers of defense between the hazards and people or assets at risk from

Fig.4 SHEL modeloperations. However, the layers are rarely

Fig.5 Swiss cheese modelperfect, with holes like a slice of Swiss cheese. The hole of the cheese shows the problem of each item when thinking these four protective barriers to be "Worker", "Tool and equipment", "Working environment", and "System of management" for instance. The position and size of this hole changes by the situation, and always swings. An accident occurs when penetrating through this hole as various factors come in succession. It is pointed out that such a factor often originates in systematic backgrounds of an organizational climate and a corporate culture. Therefore, to avoid accident, it is shown that it is indispensable to plan effective measures to prevent the hole of the cheese in each hierarchy level.

4.CONSTRUCTION SAFETY MANAGEMENT

Construction industry is featured by many dangerous works in height, use of heavy industrial machines, and different working conditions such as order-received production. Consequently, a lot of risky work exists during construction process. The fatal accident ratio accounts for about one third of the overall industry, being extremely high compared with another industry.

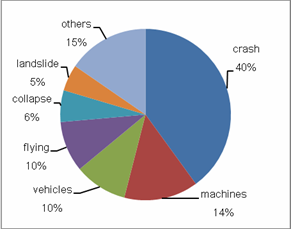

Fatal accidents in construction industry is generated in order of crash and falls(40%), construction machines(14%), vehicles(10%), coming flying falls(10%), collapse(6%)

and landslide(5%), according to thestatistics of the construction industrial accidents in 2008. Crash and falls, construction machines including cranes, vehicles and flying are the four major disasters, accounting for more than 70 percent of the whole disasters.

The construction industry has characteristics where systematization and making to the manual are difficult,because neither the content of work nor the working condition is constant. Therefore, the industrial accident

Fig.6 Classification of fatal accidentsgenerated by the construction industry has very many things resulting from un-safe action. To such a problem, various researches have been performed from the viewpoint of human error prevention up to now.

For instance, Japan Federation of Construction Contractors made the prevention measure cases based on disaster collection. Namely, disaster cases are classified into nine human error factors, such as inexperience, dangerous disregard, and shortcut action and the prevention countermeasure corresponding to it is taken. There is another example, it shows an idea analyzing the industrial accident by the matrix of un-safe action and management responsibility; it is classified into management responsibility of 10 is set to M for an un-safe state, eight human defects set to H for un-safe action, and it is analyzed the cause of the disaster and measures, paying attention to the combination of M and H. In the Research Institute of Construction and Economy developed the construction version of analyzing a human error based on the technique developed in Electric Power Industry. In addition, HEART (human error analysis and recurrence prevention) technique, to plan the cause analysis and measures by using it is proposed.

Thus, it is a stage where the analysis technique for chiefly paying attention to a human error is examined in the construction industry. It will be thought that it is necessary when various factors in which it influences the behavior of the individual such as the organizations and systems of management are widely analyzed as human factors and it takes steps to meet the situation.

5.CONCLUSIONS

In this research, the basic idea described in "Industrial accident prevention" of Heinrich, a pioneer of industrial safety, was studied. In addition, it introduced the necessity of the re-examination from a current viewpoint. It can be said that the concept of "Heinrich's premises" is still a very valuable idea. The idea that a major injury will occur before long in an environment where a lot of minor incidents exist is quoted in many fields, though there are various opinions for the composition ratio of "Heinrich's premises". An important idea is not in an actual numerical value but exists in the point to have presented such an idea.

An analysis on humanity factor side that existed in the background of the error came to be advanced in the research afterwards based on such details. The analysis technique by the SHEL model and the systematic analysis method by the Swiss cheese model were shown as an example of analyzing human factors. Especially, it was pointed out that working on the construction of the overall safety management system by which layers of management contained the organization was extremely important in the safety management of present industry under a complex system.

It could be possible to classify it into "Human model" and "Organizational model" by arranging these from the viewpoint of the technique of the safety management. A typical idea of a current safety management is "Human model". For this model, a worker is regarded as the individual who can act freely from safe behavior to unsafe practice. This model has been most widely employed, and it can be said that it is a technique with the longest history in which it is used continuously since the early stage when the industrialization started in a lot of industrial fields.

"Organizational model" is comparatively a new kind of thinking seen as a result after a human error is assumed to be a cause. The error is generally considered to be a symptom that shows the existence of the potential cause in the system. In this model, continual management of a preliminary measure for safety maintenance and a basicprocess of a system are needed. In that sense, it can be considered a common conceptsimilar to total quality management.

The construction industry is labor concentration type, and when considering a future safety control, an analysis of human factors side becomes very important. An approach for a new safety management system for referring to "Organizational model" will be very useful in the future. An effective analysis for the construction industry should be likely to be done referring its industrial characteristics. An approach of a new safety management system is required in consideration of all elements that surround workers, after having taken countermeasures at a basic individual level.

REFERENCES

- 1. Manuele, F.; Heinrich RevisitedTruism or Myths, On the Practice of Safety, WileyInterscience, pp.122146, 2003.

- 2. Heinrich, W.; Industrial Accident Prevention, McGraw-Hill, pp.1365, 1959 (Fourth Edition).

- 3. Bird, F. and Germaine, L.; Practical Loss Control Leadership, DNV (USA) Inc., 1996.

- 4. Human Factors Research Center; Human Factors Analysis and Evaluation Technique (JHPSE), Central Research Institute of Electric Power Industry, 1990.

- 5. Hawkins F.; Human Factors in Flight, Ashgate publishing Ltd., 1993.

- 6. Reason J.; Managing Risks of Organizational Accidents, Ashgate publishing Ltd., 1997.

- 7. Hojo, T.; Safety Education in Construction Engineering, Proceedings of the XVIIth World Congress on Safety and Health at Work, USA, 2005.

- 8. Takagi M.; Prevention Countermeasure of Human Error in Construction Industry, Chosakai Inc., 2000.

- 9. Coble R., Hinze J. and Haupt T.; Construction Safety and Health Management,

Prentice-Hall Inc., 2000.