Introduction

The amount of radiant heat gained or lost by the body can be considered as the algebraic sum of all heat fluxes exchanged by the exposed parts with all the existent heat sources. The radiation that a subject is exposed in the work place can be determined by the average of the radiant temperature [3]. The usual way to evaluate that is based on the measurement of dark globe of 150 mm diameter temperature. However the globe can have different sizes in diameter and to do so, the appropriate formula must be applied to calculate the average of radiant temperature, since it is dependent of the globe diameter [1].

In an overall manner the radiant temperature average, can be defined as the sum of the existing surface temperatures were the subject is, taking in account the incident solar radiation, that as an higher impact than the environment temperature. This average is the easier way to describe a radiant environment but it has some limitations. When is necessary evaluate hot environments the risk evaluation method for thermal stress most commonly used is the WBGT index (Wet Bulb Globe Temperature). However this diagnostic method allows us to discard or accept the necessity of having another method, with higher complexity [5].

The dark globe thermometer is composed by an hollow sphere with a thermal sensor inside. The exterior surface of the globe absorbs the total radiation from the walls and heat sources in a defined space, behaving as a dark body and is emissivity it is closed to the unit (εg = 0,95). For this effect, the surface of the globe is electrochemically coated or painted in dark mate. The thermometer when placed in a desired spot it reaches an thermal equilibrium after a while. Is this equilibrium temperature that we call globe temperature (Tgn). This value is the average between the temperature inside the globe (thin layer) and the air temperature inside the same (closed space), witch is identical to the exterior temperature. The temperature inside the globe translates the heat balance exchanged between the heat sources and the air convection, and this balance can be quantified in the radiant temperature average [4].

The standard dark globe of 150 mm diameter presents different disadvantages in its use, as its dimension and the waiting time for the result. It’s evident the necessity of using a smaller equipment, easier to transport and with a quicker time of response. For the WBGT index calculation, the market offers a wide range of equipment with smaller dimensions, although the temperature in the dark globe affects the determination of the WBGT index. The measurement made with a lower globe than the standard one, can not be used directly to calculate the WBGT index proposed by the norm ISO 7243:1989 [4].

For this reason to determine the WBGT index is necessary to introduce a suitable correction factor that allows the correct transposition of the temperature in the dark globe of 50 mm (Tgn50) to the temperature in the standard globe of 150 mm (Tgn150).

Methodology

This work presents the results of different assays for the evaluation of the dark globe temperature using a standard dark globe thermometer (Delta OHM HD2307.0 RTD) and three dark globe thermometer of 50 mm diameter (Casella Microtherm Heat Stress WBGT; Casella B.S.2842:1992 AO5497; Delta OHM HD32.2 WBGT Index).

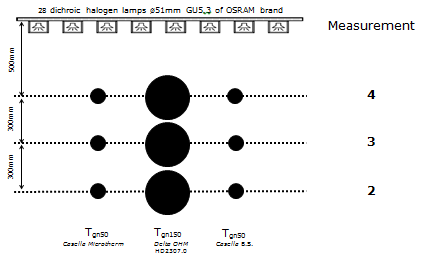

To perform the assays, the Oliveira’s guidelines were followed, with the exception that it was built a panel with 28 lamps with different characteristics from those used in the study (halogen dichroic lamps ø51mm GU5,3 brand OSRAM). The schematic representation of the assay is presented in Figure 1. It was used a standard dark globe thermometer (Delta OHM HD2307.0 RTD) and two dark globe thermometer of 50 mm diameter (Casella Microtherm Heat Stress WBGT; Casella B.S.2842:1992 AO5497). In this assay the first measurement is performed in dark room environment, before the measurements with the light panel on.

Figure 1 - Schematic representation of the assay (panel with 28 lamps)

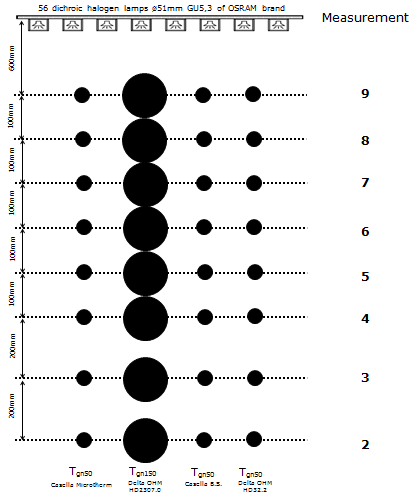

Having in account that the results obtained by Oliveiras’ have values below 40ºC for the standard dark of 30mm diameter, we raised the amount of lamps to 56 to enhance an environment were the temperature in the dark globe reaches 50ºC. To develop the numeric correction factor for the 50 mm diameter is necessary to use higher temperature range. The schematic representation of the assay is presented in Figure 2, where is represented all the equipment used in this study. In this assay the first measurement is also performed in dark room environment, before the measurements with the light panel on.

Figure 2 - Schematic representation of the assay (panel with 56 lamps)

Results and Discussion

When the standard globe and the 50 mm globe are placed at the same distance from the heat source, the lower dimensions sensors presented a smaller globe temperature. So it is necessary to use a correction factor suitable for the correct transposition of the temperature in the dark globe of 50 mm (Tgn50) to the temperature in the standard globe of 150 mm (Tgn150).

After the determination of Tgn values on the equipment used in this study it was necessary develop a calibration curve for better describe the equation that represents its behavior. When found the difference between the result of a 150 mm diameter globe and the 50 mm globe it is possible to correct the Tgn value obtained in the equipment of registered temperatures. The Tgn(corrected) value will be the sum between the value in the 50 mm and the y found by the given equation that establish the temperature difference between globes.

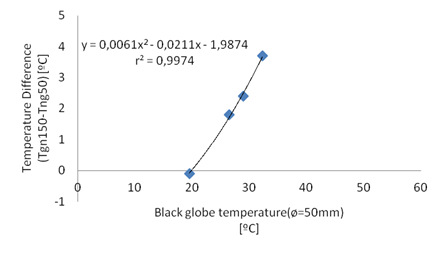

The calibration curve presented on figure 3 allows us to determine, from the 50 mm globe temperature (Casella Microtherm Heat Stress WBGT; Casella B.S.2842:1992 AO5497), the difference between the Tgn150 and Tgn50, for the temperature range studied. This value were obtained accordingly to the schematic representation in figure 1, were a maximum temperature of 32,3ºC was obtained.

Figure 3 – Calibration curve of the difference between Tgn150 and Tgn50

The development of the calibration curve allows us interpolate the results obtained with the equipment used in the study. The equation described in figure 3 was found using globes with globe temperatures that not represent a stressed environment, so the equation can not be used to correct the Tgn for hot environment with risk of thermal stress.

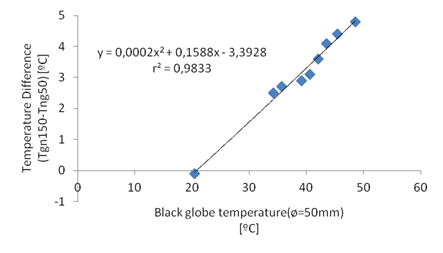

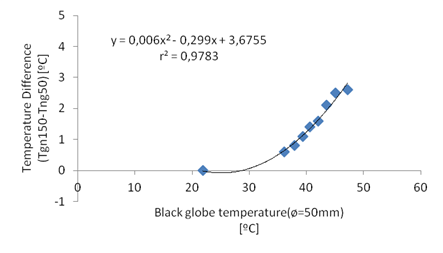

The calibration curve presented on figure 4 allows us to determine, from the 50 mm globe temperature (Casella Microtherm Heat Stress WBGT; Casella B.S.2842:1992 AO5497), the difference between the Tgn150 and Tgn50, for the temperature range studied. This values were obtained accordingly to the schematic representation in figure 2, were a maximum temperature of 48,5ºC was obtained.

Figure 4 - Calibration curve of the difference between Tgn150 and Tgn50

On figure 5 is presented the calibration curve that allows us to determine, from the 50 mm globe temperature (Delta OHM HD32.2 WBGT Index), the difference between the tgn150 and tgn50, for the temperature range studied. This values were obtained accordingly to the schematic representation in figure 2, were a maximum temperature of 47,2ºC was obtained.

Figure 5 - Calibration curve of the difference between Tgn150 and Tgn50 [Temp. máx. 47,2ºC]

For warm thermal environment with risk of thermal stress, between the range of temperatures studied and with the same equipment, the value obtained from the globe temperature (Tgn) can be revised. When found the difference between the result obtained with the 150 mm globe and the 50 mm globe (y), the Tgn value have to be revised for a Tgn(correct) value. This value the sum between the value in the 50 mm globe and the y found by the given equation that establish the temperature difference between globes accordingly to the expression (1).

|

Tgn(correct) (ºC) = Tgn + y |

(1) |

Conclusions

In this study is possible to verify that exist differences between the measurements made by globes with different dimensions from the standard one. The 50 mm globes placed at the same distance from the heat source showed lower temperature values and there were differences between the equipments used. For this reasons, for the calculation of the WBGT index, it is necessary introduce a correction factor that allows the correct transposition from the 50 mm globe temperature to the temperature of the standard globe.

It is important to refer in this study that it lacks of a dipper investigation, since the necessity of using a climatic chamber where it is possible to determine the evaluated issues without interference of external temperatures.

For the thermal conditions determination in the work place is practical the utilization of lower globe dimensions from the standard one. They are easier to use, cheaper, lighter and do not need a wide space to make the measurements. and this study is particularly interesting because allow its use in a correct manner.

Acknowledgments

A preliminary version of this paper has been presented at ORPconference 2014.

References

- 1. ISO 7726:1998. ”Thermal Environments Instruments and Methods for Measuring Physical Quantities”, International Standard, Second Edition, Geneve, International Organisation for Standardisation, 1998

- 2. ISO 7243: 1989. “Hot Environments Estimation of the Heat Stress on Working Man, Based on the WBGT index (“Wet Bulb Globe Temperature”)”, International Standard, Second Edition, Geneve, International Organisation for Standardisation, 1989

- 3. Lamberts, R. et al (2012). Conforto e Stress Térmico. Disponível em URL [Consult. Jun 2013]: <http://www.labeee.ufsc.br/antigo/arquivos/publicacoes/Apconforto.pdf>

- 4. Oliveira, A. et al (1998). Desenvolvimento de um Termómetro de Globo Para a Avaliação de Ambientes Térmicos Variáveis. Departamento de Engenharia Mecânica Faculdade de Ciências e Tecnologia da Universidade de Coimbra.

- 5. Silva, H (2013). Ambiente Térmico e Ventilação – Avaliações práticas e controlo. Lisboa: Edições Silabo. ISBN: 9789726187257

Papers relacionados