Most of studies begin highlighting the high levels of accidents and the unsafe conditions of construction industry (Jin et al., 2019). This affects its incident rates, the higher than the average of other industries (Bavafa, Mahdiyar, & Marsono, 2018; Nahangi, Chen, & McCabe, 2019; Zhang, Chi, Yang, Nepal, & Moon, 2017).

There is a diverse direction in actual research in construction safety, one of the chief is related with safety management, risk analysis and safety assessment. Additionally information and communication technologies (ICT) have emerged in construction sector (Jin et al., 2019).

A safety management system (SMS), essential to manage construction safety (Teo and Ling, 2006), includes always safety performance measurement and evaluation (Zhang et al., 2017). That is related with the need to control the critical, especial and changing safety conditions on sites that needs continuous surveillance and improvement (Gunduz, Talat Birgonul, & Ozdemir, 2018)(Carter and Smith 2006).

In a continuous changing environment as construction site, is necessary to check if previsions and real safety conditions go together. Safety inspections are vital to guarantee that SMS is working as expected (Bavafa et al., 2018; Nahangi et al., 2019). Despite the importance of this issue, there are a limited number of researches exploring it in depth (Zhang et al., 2017). One of the big problems collected in the literature is the efficiency and limitations of actual safety inspections (Zhang et al., 2017; Zou, Lun, Cipolla, & Mohamed, 2017). Collecting data through the traditional paper systems is tedious, inefficient and an error-prone system (Xu, Chong, & Liao, 2019; Zhang et al., 2017; Zou et al., 2017).

On the other hand, most of construction sector is formed by small and medium firms, which is translated into construction sites with low levels of structure and resources coming from main agent. We are referring to the crew specifically commanded firstly by constructors and secondly by promoters. Because of that, any technology and message or instructions for intervention must be clear and concrete; on the contrary, all onsite inspection investment will be lost in the way, because the information will be unable to reach the person that has to materialize the intervention.

There is a need of an approach more based on inspections that improves efficiency and completeness. This approach should considers the proximity between safety inspections and other safety management strategies. There is a lack of structural approaches that connect these issues of safety inspections and safety management strategies (Zhang et al., 2017).

Moreover, each construction site has its own structure and resources that influences over physical site conditions, affecting first its levels of risk (Forteza, Carretero-Gómez, & Sesé, 2017a) and finally, increasing the accident rates (Forteza, Carretero-Gómez, & Sesé, 2017b). Academic research has provided a few tools to assess this level of risk on site, however it has been mainly focused on the validation of the different assessment processes (Forteza, Sesé, & Carretero-Gómez, 2016) and not so much on providing clear guidelines or specific set of criteria for interventions (Gunduz et al., 2018). There is “a need for more efficient and effective information management systems for construction” that avoids the inconveniences of paper working (Zou et al., 2017). It is just possible using new ICT technologies to improve site conditions (Zou et al., 2017).

This work contributes to the existing literature adopting a fully prescriptive approach to fill this gap. As current prevention strategies do not yield better safety levels (Hinze, Hallowell, & Baud, 2013; Sousa, Almeida, & Dias, 2014), we propose an app that captures live physical conditions, structure and resources available on site, assess the level of site risk and offers, as a result, a set of criteria for early intervention. This is the most relevant contribution of our applied research, the app RISGEST.

The goal of this research is to design, develop and implement an application for mobile devices facilitates the use of the CONSRAT methodology for risk assessment (Forteza et al., 2016), and directs the attention into onsite interventions and problems solving. This app allows any qualified technician to assess the organizational structure, resources and material conditions and, as a result, obtain a specific set of criteria for interventions. Of course, the app will be useful and informative also for the promoter and constructor.

Since internal and convergent validation of CONSRAT model has been already reported (Forteza et al., 2016), another objective of this paper is to carry out a discriminant validation of that model using the app to assess three sites, as case studies, with a different level of risk through a mechanism independent and external.

Our main practical implication is related with the transfer of previous research into a practical tool through the development of an application for mobile devices that generates clear and focused criteria for interventions in each specific construction site and work.

The app is theoretically grounded upon a risk on site model, which specifies and identifies the specific connection paths between the organizational variables and the risk variables (Forteza et al., 2017a). Our app not just facilitates criteria for intervention over safety material conditions on site, but also identifies which are the most important improvements in relation to site structure and resources.

This study contributes in the programing of a safety management system with a useful interface with a mobile application, adopting the new ICT tendencies that correct the problems of previous systems based on work-paper. Taking into account the multiplicity of factors that join in each risk and precursors, this study determines the most important and adequate issues for prevention and intervention derived from a set of questions and assessments.

After a deep literature review, and also based on our previous research, we propose a relationship structure of the different risk variables and organizational factors. The purpose of this relational model is to drive and focalize safety site inspections and their subsequent interventions.

Risk assessment versus organizational and resources assessment.

The app is based on the Forteza et al.'s (2016) study that developed a tool capable to capture the specificities of sites that have influence on risk, and another research that connects risk variables with the organizational ones (Forteza et al., 2017a).

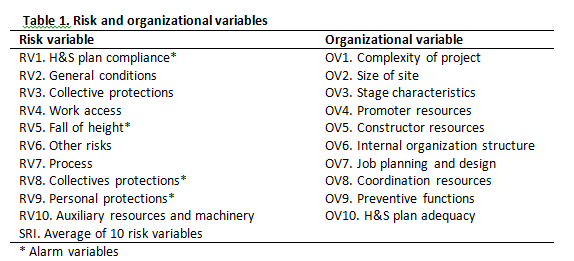

Table 1 shows the composition of risk and organizational variables.

The construction of each variable is detailed in Forteza et al., (2016). Each risk and organizational variable is formed from the different combination of some items that each technician must to evaluate. Risk variables are coming from continues changing live conditions of sites, while the nature of organizational variables is more static. Because of that, each construction site has a single assessment of items affecting organizational variables and multiple and continues assessment of items composing risk variables.

The interventions derived from the results of the assessment of risk variables are straightforward. Using general valuation criteria, each item is classified under one of the three levels of assessment reported in the Table 2. Coming from that, we obtain direct criteria of intervention depending of the item assessed in the high range of the scale. We match each assessed score of the risk variable with a corresponding level for intervention depending on the risk range. Table 2 shows the three levels of scoring of risk variables and the corresponding general criteria for intervention. This table shows the standardized criteria common to all risk variables, while the app provides specific criteria.

.png)

Given the nature and peculiarities of the construction sector and the limited command structure in most construction sites we have mentioned above, the use of our app and the intervention criteria resulting from its assessments try to provide easy and clear guidance for practitioner on site.

After having discussed risk site assessment related issues we can turn our attention to the assessment of organizational factors. Applying the app we also obtain the results of the assessment of organizational variables. From Forteza et al. (2016) one can conclude that there are two basic types of variables: those related with complexity of site and the others related with resources. Similarly to how we have discussed about risk variables, organization variables are composed by different items all of them measured on a range between 0.00 and 1.00. In the case of organizational variables, we cannot divide this measurement range into specific intervals for pre-established levels of commitment or accomplishment. Because of the nature of those variables, there cannot be imposed any previous level of commitment within this range, mainly because each site is as specific as it has to be and the site has its own needs of resources and complexity. Due to all of this, it is not possible to know or define which specific level is the adequate.

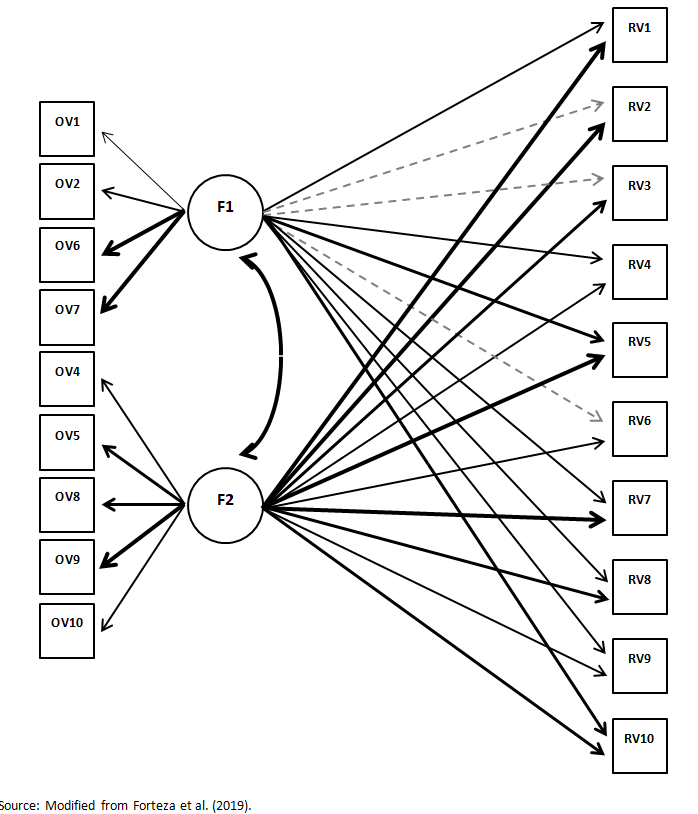

The question up to this point is how to connect safety recommendations affecting the organizational factors which have been assessed through the organizational variables at a specific site. We propose that it can be done based on Forteza et al.’s (2017a, 2019). The first research, connects risk on site factors with organizational factors. These authors connected an aggregate measure of the level of risk on site (named SRI and calculated by the average of the 10 risk on site variables) with 4 organizational factors which are measured through the clustering of 10 organizational variables of the site. Forteza et al. (2019) have recently proposed an alternative specification of the relational model connecting risk on site and organizational factors. These authors have decomposed the RSI variable into its 10 risk on site variables, and also they have aggregated the four organizational factors into two broader factors representing organizational complexity and organizational resources. Since the authors have found empirical support for this alternative specification of the model, we propose to use it to justify which prevention and safety actions should be undertake at the level of organization factors.

Figure 1 shows the main connections found by (Forteza et al. ,2019) between risk and organizational variables. As it can be seen they have found that these connections involve two main organizational factors, F1 (complexity on site) and F2 (resources on site). The thickness of the arrows symbolizes the degree of importance between issues. Therefore, it allows focalizing the most important variables for intervention at the level of the organization, in addition to the safety intervention derived directly from the measurement of the risk variables. For example, R2, General conditions on site (assessing fence, circulations, order, tidiness, among others) is manly affected by F2 (site resources). Which means that, besides the direct need of deploy an intervention on items composing R2, we have to check Organizational variables composing F2. According with the model, we have to inspect mainly what is happening for example with OV9, Preventive functions of the structure, because might be possible they are not properly or sufficiently assumed.

In summary, the theoretical and empirical background for the App RIGEST is the tool CONSRAT proposed by Forteza et al.'s (2016) and the structural model between risk on site variables and organizational factors empirically supported in Forteza et al. (2019).

Figure 1. Connections between risk and organizational variables

In this section, we offer examples of how to use RISGEST in real settings, as well as to conduct additional tests for the discriminant validity of CONSRAT.

Using RISGEST is a five steep process. First step, the technician has to fill the site register that includes site identification and characterization, developer and constructor characterization. This steep needs to be filled just only one time per site. Second step, must be completed each time an assessment is initiated. It includes data about the stage of the work and risk factors, going on with different valuations (general conditions, access of workplace in operation, falls from height, other risks, process, collective protections, anti-fall protections, auxiliary resources and machinery. The third step offers direct graphics of risk and organizational variables as we can see on Figure 2. The fourth step offers the possibility of generating different types of graphics, for example showing the evolution of one single site over the time, as well as a comparison of different sites. Finally, the fifth step gives a complete feedback report with all the information of how to intervene on site.

After steps three and five, the App RISGEST gives the possibility to send a report of the results. First report is simply the graphic of variables in Figure 2. Second report comprises a full but concrete information of the main lines to intervention on site.

.png)

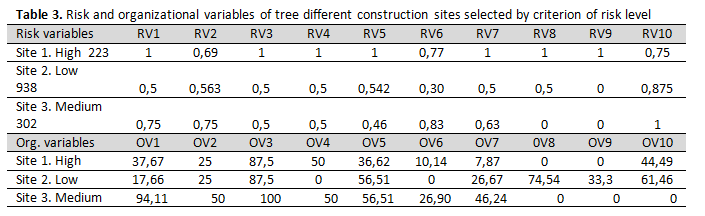

Table 3 shows the different risk and organizational variables obtained on site with three different levels of risk on site: one with high level of risk, another with low level of risk and finally the last with medium level of risk on site. This is the information obtained after the mentioned step three.

Figure 3 shows pictures corresponding to each site for the three levels of risk on site assessed

223 High 938 Low 302Medium

Finally, the App RISGEST provides a report that comprises the full information for initiating the intervention on site.

For example, in our case study 1, in addition to the graphics similar to those showed in figure nº2 we reproduce here the final report.

Construction site 1 corresponds to a small new and infill single-family house without special environment conditions and three levels (ground floor and 2 floors more). The main work stage corresponding with the visit is the structure. The promoter is professional, main constructor at head of site is a self-employed constructor, he is the contractor (direct contract relationship with promoter) and the business owner is at head of the site. There are two contractors on site, the mentioned self-employed and another one there is not subcontracting. The construction site presents just one main work, the workers, a total of tree, were on the perimeter floor. There is no documented to demonstrate health and safety coordinator, therefore there is not documented work from his/her. The health and safety plan is on site but is previsions are unknown for the interlocutors on site. All this information is aggregated to conform the mentioned organizational variables.

Report of site 1:

Risk variables:

RV1: The fulfillment of the PSS is critical and unacceptable, it should proceed to the exhaustive review of the breaches, take measures for its correction and put the adequate control measures so that this low level of compliance is not reiterated

RV2: The conditions of implementation of the work are critical and unacceptable, it should proceed to take immediate action to rectify and control them periodically

RV3: The collective protections of the work are critical and unacceptable, it should proceed to the immediate revision of them and their correction, reorganizing the systems of periodic control. This is an aspect of radical importance for the safety of the work and its prolongation over time could have serious consequences. Assess whether work interruption measures should be taken until the level of this risk has been remedied

RV4: The access to the main pit is unacceptable, it should proceed to the immediate revision of the same taking measures for its correction, as well as its periodic control. Access to the pit, especially if it coincides with the risk of falling from height, can be a key aspect for the safety of the work

RV5: The risk of falling from height is critical and unacceptable, you should proceed to review it and its permanent control. The control of this risk is key to the level of security in the work, the current levels must be corrected immediately. Assess whether work interruption measures should be taken until the level of this risk has been remedied. Specificities: The risk of falling height is more than 6 meters, the level of deficiency is very high (there is no protection or is very deficient), the exposure is permanent, the probability and severity of fall is very high, an immediate intervention is required

RV6: The other risks identified in the work are unacceptable and / or have a greater incidence on the risk of falling from height. It should be revised, corrected and checked periodically. Other risks identified: Falls at the same level, falling objects, landslides, cuts, entrapments or collisions, overloads. A specific incidence of these risks on the risk of falling height is detected

RV7: The process is not adequate and / or presents important deviations. The process and / or means of control must be reconsidered to ensure compliance without deviations

RV8: The collective protections (CP) in the pit are unacceptable, it is necessary to proceed to the immediate rectification of the deficiencies detected and their subsequent periodic control to avoid repetitions in the deficiencies of the collective protections. The CP is a critical aspect for the level of security of this phase, any deficiency must be corrected immediately preventing the continuation of the development of the pit. Specificities: there are no networks installed or their installation is completely inappropriate, there are no guard rails or their installation is completely inappropriate. No protection boards or poor installation

RV9: The personal fall protection in the pit is unacceptable, it should proceed to the immediate rectification of the deficiencies detected and its subsequent periodic control to avoid repetitions. Fall preventive systems are a critical aspect for the safety level of this phase, any deficiency must be corrected immediately, it cannot be continued the development of the pit. Specificities: the fall preventive system does not adapt to the pit, it is necessary to install new personal protections

RV10: The auxiliary equipment and machinery in the pit are unacceptable, it is necessary to proceed to the rectification of the critical deficiencies. The control of the auxiliary means and machinery is key for the safety of this construction phase, so any lack of adaptation should be reviewed immediately.

The critical risk values detected in all the risk variables (RV) require an intervention on the material conditions of the work and also on its resources according to their level of complexity

The main interventions at the level of organizational complexity and resources are the following:

Complexity: The high levels of risk in general and specifically the risk of falling from height and the one related to auxiliary means and machinery can be related to the complexity of the work. This work presents in the pit has been evaluated, a complexity derived from the planning and design of the work and organizational structure in which the type of contracting (several small contractors) may affect as well as the location of the workers in the pit (perimeter of slabs and forged without protection)

Resources: The high levels of risk detected in the site, in particular in the risks of compliance with the safety plan, general conditions, fall from height and auxiliary means may be related to the lack of resources on site. Specifically, the resources that can most affect are the developer's resources (promoter’s support and own resources in the support of the site safety) and builder’s (available resources according to the type of constructor and the adequacy and proficiency of the person in charge of the site), the coordination resources (designation and actions of the health and safety coordinator, documented activity), preventive functions (involvement in health and safety of the managers and commands of the site), adequacy of the safety plan in the site (presence and adequacy of contents)

As it can be seen the graphics and reports focus in an global manner into interventions on the construction sites.

The main objective of this research is design, develop and implement an application for mobile devices that help practitioners to conduct a solid assessment of the risk on construction sites and identify broad areas to intervene to reduce the level of risk.

We have shown how the App RISGEST has been designed upon theoretical and empirical models that served to assess the risk on construction sites, on one side, and the relationships of risk on site factors with organizational factors, on the other hand. RISGEST subsumes both models theoretical and empirical insights and, taking advantage of ICT, allows that any technician or competent practitioner undertakes an easy evaluation of the risk on site and provide clear focus towards the critical improvement actions that need to be done. The App RISGEST can be taken as an instrument to bridge the gap between the management of safety (preventive policies) and the management of organizations (endowment strategy).

Althoug the App RISGEST is currently under testing and refining, we believe it is a good, easy and attractive tool in order to enrich the safety management systems with a versatile

Despite the benefits of the App RISGEST, several improvements need to be undertaken that open the roads for future empirical studies.

Bavafa, A., Mahdiyar, A., & Marsono, A. K. (2018). Identifying and assessing the critical factors for effective implementation of safety programs in construction projects. Safety Science, 106, 47–56. https://doi.org/10.1016/j.ssci.2018.02.025

Carter, G., and Smith, S. (2006). “Safety hazard identification on construction projects.” J. Constr. Eng. Manage., 10.1061/(ASCE)0733-9364 (2006)132:2(197), 197–205.

Forteza, F. J., Carretero-Gómez, J. M., & Sesé, A. (2017a). Effects of organizational complexity and resources on construction site risk. Journal of Safety Research, 62(Supplement C), 185–198. https://doi.org/10.1016/j.jsr.2017.06.015

Forteza, F. J., Carretero-Gómez, J. M., & Sesé, A. (2017b). Occupational risks, accidents on sites and economic performance of construction firms. Safety Science, 94, 61–76. https://doi.org/10.1016/j.ssci.2017.01.003

Forteza, F. J., Sesé, A., & Carretero-Gómez, J. M. (2016). CONSRAT. Construction sites risk assessment tool. Safety Science, 89, 338–354. https://doi.org/10.1016/j.ssci.2016.07.012

Forteza, F. J., Carretero-Gómez, J. M., & Sesé, A. (2019). “Organizational predictors of risk on construction sites”. Working paper.

Gunduz, M., Talat Birgonul, M., & Ozdemir, M. (2018). Development of a safety performance index assessment tool by using a fuzzy structural equation model for construction sites. Automation in Construction, 85, 124–134. https://doi.org/10.1016/j.autcon.2017.10.012

Hinze, J., Hallowell, M., & Baud, K. (2013). Construction-Safety Best Practices and Relationships to Safety Performance. Journal of Construction Engineering and Management, 139(10), 04013006. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000751

Jin, R., Zou, P. X. W., Piroozfar, P., Wood, H., Yang, Y., Yan, L., & Han, Y. (2019). A science mapping approach based review of construction safety research. Safety Science, 113, 285–297. https://doi.org/10.1016/j.ssci.2018.12.006

Nahangi, M., Chen, Y., & McCabe, B. (2019). Safety-based efficiency evaluation of construction sites using data envelopment analysis (DEA). Safety Science, 113, 382–388. https://doi.org/10.1016/j.ssci.2018.12.005

Sousa, V., Almeida, N. M., & Dias, L. A. (2014). Risk-based management of occupational safety and health in the construction industry – Part 1: Background knowledge. Safety Science, 66, 75–86. https://doi.org/10.1016/j.ssci.2014.02.008

Teo, E. A. L., and Ling, F. Y. Y. (2006). “Developing a model to measure the effectiveness of safety management systems of construction sites.” Build. Environ., 41(11), 1584–1592.

Xu, Q., Chong, H.-Y., & Liao, P.-C. (2019). Collaborative information integration for construction safety monitoring. Automation in Construction, 102, 120–134. https://doi.org/10.1016/j.autcon.2019.02.004

Zhang, H., Chi, S., Yang, J., Nepal, M., & Moon, S. (2017). Development of a Safety Inspection Framework on Construction Sites Using Mobile Computing. Journal of Management in Engineering, 33(3), 04016048. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000495

Zou, P. X. W., Lun, P., Cipolla, D., & Mohamed, S. (2017). Cloud-based safety information and communication system in infrastructure construction. Safety Science, 98, 50–69. https://doi.org/10.1016/j.ssci.2017.05.006