Draghici, AncaPolitehnica University of Timisoaraphone: 0040-256-403610, adraghici@eng.utt.roNitulescu, MirceaTransilvania University of BrasovMocan, MarianPolitehnica University of TimisoaraProstean, GabrielaPolitehnica University of Timisoara

Draghici, AncaPolitehnica University of Timisoaraphone: 0040-256-403610, adraghici@eng.utt.roNitulescu, MirceaTransilvania University of BrasovMocan, MarianPolitehnica University of TimisoaraProstean, GabrielaPolitehnica University of Timisoara

ABSTRACT

The present paper develops a proposed methodology for the ergonomics design using CATIA V5 software. The main objective is ergonomics design and analysis in the case of a particular work place. By using the following modules: Human Builder, Human Measurements Editor, Human Posture Analysis and Human Activity Analysis there have been evaluated the worker’s strain and tiredness degree. The design process c onsidering the ergonomics facilities offer by CATIA V5 can be apply for products, processes or systems. The paper proposes methodology for the ergonomics design based on the CATIA V5 ergonomic module.

Keywords:

computer-aided ergonomics, virtual design, postural analysis, tiredness evaluation

GENERAL ASPECTS

Having to respond to a wide range of strains, man holds a central place in the systemic concept imposed by the addressing of the man - strains system. The essence of balance within the man – strains system resides in the achievement of correct proportions of the simultaneous action of strain factors and the capacity of the human organism subjected to strain [1, 2, 5].

This is actually also the condition for the functioning of the man – strainssystem and the achievement of its objectives. In the view of ergonomic type scientific research the interaction of the human operator and the working means is generally defined by the man- machine system [2]. The notion of machine is widely used, starting from the concept that it is a technical means for energy transformation into useful mechanical work till including those means that amplify the force of the human operator during the production process. The ergonomics research is focused on the man- machine relation study or the user interface [2, 9].

Considering man the central factor of rational and efficient use in worksystems has led to the generation of new concepts of design and re-design, with a large degree of applicability and considerable technical-economical advantages [3, 9]. One of the most important problems of the user-oriented design process is the ergonomics principles using and implementation. The ergonomics design is related to the product and process where is important to analyse and optimise the user interface [7, 8, 9, 11]. Nowadays the ergonomic design process is computer aidedby using different specialised software or even specialised modules attached to CAD or CAM products. This is the case of CATIA V5 software that has appeared as a result of the collaboration between IBM and Dassault Systems France. CATIA Version 5 is an integrated suite of Computer Aided Design (CAD), Computer Aided Engineering (CAE), and Computer Aided Manufacturing (CAM) applications for digital product definition and simulation [10].

The software is generally addressed to solve many engineering activityproblems. The design process start point is the creation of a three-dimension model of the design piece (assembly). Simultaneously the CAD process using CATIA V5 allowed us to make: engineering calculation, manufacturing simulation together with NC programs for them, complex placement draws (plans) for different production systems, electrical and electronically diagrams and ergonomics studies. All these facilities are poss ible using the new IBM concept of modularization. So, different designers can use specific modules of the software adept to their practical design needs [10].

ASPECTS RELATED TO E RGONOMICS DESIGN USING CATIA V5

The process of ergonomics design using CATIA V5 is possible by using the Ergonomics Design & Analysis module. After implementing the ergonomics facilities we obtained a CATProduct [4]. The ergonomics design process is define by the following modules that have to be used in the same order, as they are present:

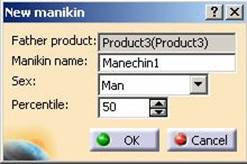

a. Human Builder allowed us to define and create the probable user of the product or system that is, in fact, the human operator (worker) represented by a

manikin. For a new user (human body) definition we use the New manikin command (figure 1). Here we have to select the product or the system where the manikin will be implement for the user interface study development (father product). We have to define the manikin sex and the correct percentile (‰) for the human body dimension corresponding to the probable worker’s body dimensions (considering Gauss

|

|

Figure 1. New Manikin box dialoguedistribution). The results of this process are shown in figure 2 and 4. |

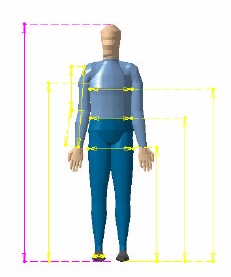

Figure 2. The created manikin [4, 6]

Figure 3. The manikin dimensions that can bemodify [4, 6]

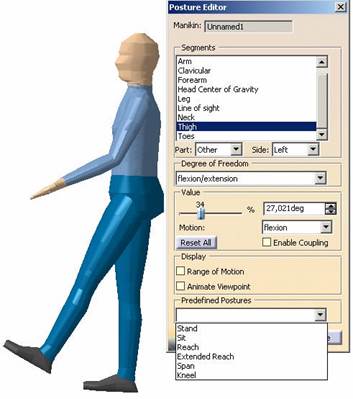

The manikin can be manipulated as is needed in the design process. Also, it can be settled in a determinate position like: Stand, Sit, Reach, Extended Reach, Span or Kneel and it could be free move by using the Posture Editor command or directly with Forward Kinematics.

|

|

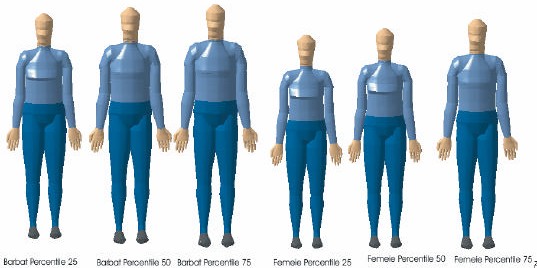

Figure 4. The manikin definition considering the sex and percentile criterion |

b. Human Measurements Editor allowed the designer to personalise the manikin. This module is very flexible and simple to use (figure 3). In figure 5 is shown the variable edition window.

Figure 5. The manikin’s variable edition

It can be observe that we have two possibilities for variable edition. The designer can tape the variable value or he can adjust it. The second possibility is better because the variable value can not succeed the limits that are determinate by the manikin constitution.

After we have establish the manikin’s type and dimension we have to choosethe work position by a correct manipulation of the object. The Forward kinematics command allowed us to move the different manikin’s body segments very easy and directly. The Posture edition command allowed us to mo dify the manikin’s body segments by selecting them from a additional list as it is shown in figure 6.

Figure 6. The posture editor

Finally, the correct posture is established. Considerring the final case study that will be presented, in figure 7 is shown the work position.

Figure 7. The establish work position

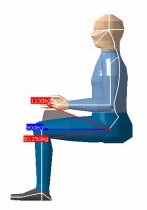

c. Human Posture Analysis allowed the designer to develop the posture analysis after the manikin definition is complete. By using the Posture analysis command we can edit the angular limits of some human body (manikin) segme nt. For example: if the manikin position is sitting we edit the femur limitation as is presented in figure 8.

a. b.

|

|

Figure 8. Posture analysis [4, 6] a) The admitted values of the femur angles b) Angular limitation for the sitting position of the manikin |

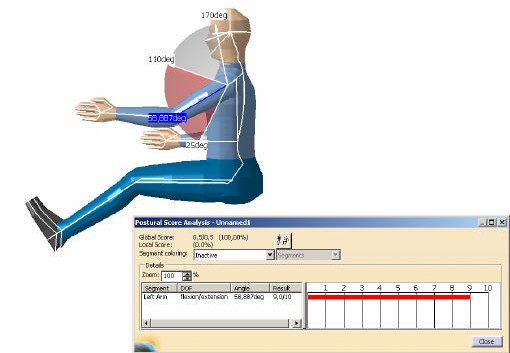

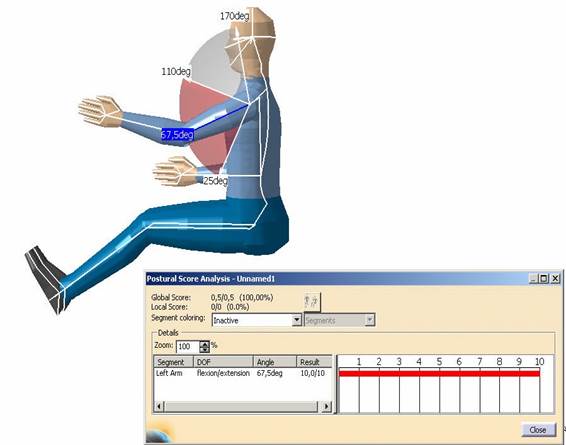

After we have edit all the angular limitation for all the human body segments we have to evaluate the posture. The system can easy establish the global score (maximum 10 minimum 1) of the posture and the score for some details corresponding to the manikin different segments position. Figure 9 shows the dialogue box for the final Postural Score Analysis.

Figure 9. Postural score analysis

Based on the score value we can appreciate if a posture is conformable or we have to optimise it. The designer can do this process or the software module has the possibility for automate optimisation of the posture by considering the angular limits given by the designer. Optimize the posture command from the dialog box Postural score analysis can assure a correct, perfect result for the optimisation (the score value is 10, and the result is present in figure 10).

Figure 10. Optimisation of the Postural score analysis

d. Human Activity Analysis allowed us to develop dynamic strain analysis for an adopted position of work activity. In this context we can evaluate the tiredness degree for a human operator that lifts a weigh with a particular frequency, we can determine the maximum weight that can be push or pull by the human operator etc. [8, 10].

The main ideea of using this CATIA’s module is the evaluation of the tirednessdegree caused by the adopted posture of the worker. The main ergonomics evaluations and analysis are:

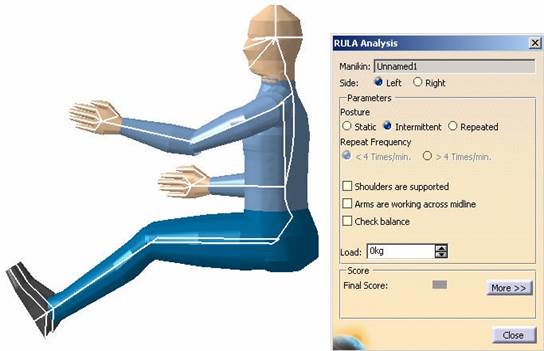

D RULA analysis (Rapid Upper Limb Assessment) that allowed us to evaluate the occupational risks that can appear at the worker’s hand level considering the determinate work condition. In figure 11 we present the RULA analysis box dialog. This method is the most use for the tiredness investigation.

D Lift/Lower analysis allowed us to evaluate the tiredness degree that is induced by weigh manipulation (lift or lower of heavy objects). The analysis started by establishes the initial and the final positions of the move. Then the tiredness degree can be evaluated by using the following methods:

./ NIOSH 1981 based on the tiredness degree analysis in the case of a weigh lift using a symmetric move of both hands without turning the superior part of the body with a maximum anvergure of 75 cm.

./ NIOSH 1991 is an extend method of the first one where applied in the case of weigh lift using an asymmetric move of the hands.

./ Snook and Ciriello is similar with NIOSH 1981 but allowed us to determinate the tiredness degree depending on the length of the movement.

./ Push/Pull analysis allowed us to establish the tiredness degree in the case of weight’s push or pull movement and it is similar with the Snook and Ciriello analysis.

./ Carry analysis allowed us to determine the tiredness degree when the worker is moving and carrying a considerable weight.

Figure 11. Dialog box for RULA analysis

ERGONOMICS PRODUCT DESIGNS USING CATIA V5

In figure 12 we present a proposed methodology for the ergonomics design & analysis (EDA) using CATIA V5 that can be adopt if the product or the work system is already define or exist. In this case the feedback operations determine a large number of iteration and changes for the pre -design product. In this case the Ergonomics Design and Analysis module from CATIA is used for product evaluation and optimisation from the user perspective [4, 6, 10].

The methodology becomes more efficient (short working time and low cost of the design activities) if the product is designed after the EDA process. In this case the specific module from CATIA is used for defining the probable user (the manikin definition) and the optimal posture for the work place (product use). These mean to analyse the work positions and activities and to obtain a maximum score for them. In figure 13 is presented the EDA methodology for new product design (or work places). In conclusion, CATIA’s ergonomics design and analysis module is an interactive visual tool that can be use for different product or work system design activities.

Establish of the design conditions for the product User interfaces definition and work condition analysing

Product design Work system design

Ergonomics design & analysis

1. Human Builder

|

|

2. Human Measurements Editor 3. Human Posture Analysis Postural Score Analysis 4. Human Activity Analysis |

Dynamic strain analysis and tiredness degree evaluation

![]()

OPTIMAL RESULTS:

The work activities require low human energy consumption CATProduct = a “friendly using” product

Figure 12. EDA methodology for pre-design products (using CATIA V5) [4, 6]

|

|

Establish of the design conditions for the product User interfaces definition and work condition analysing Ergonomics design & analysis1. Human Builder 2. Human Measurements Editor 3. Human Posture Analysis Postural Score Analysis 4. Human Activity Analysis Dynamic strain analysis and tiredness degree evaluation Optimal posture define Product design Work system design |

OPTIMAL RESULTS:

The work activities require low human energy consumption CATProduct = a “friendly using” product

Figure 13. EDA methodology for new product design (using CATIA V5) [4, 6]

RESULTS AND CONCLUSION

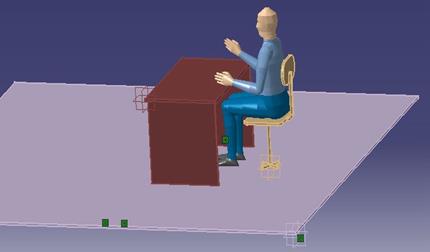

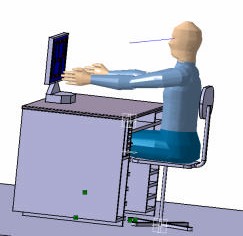

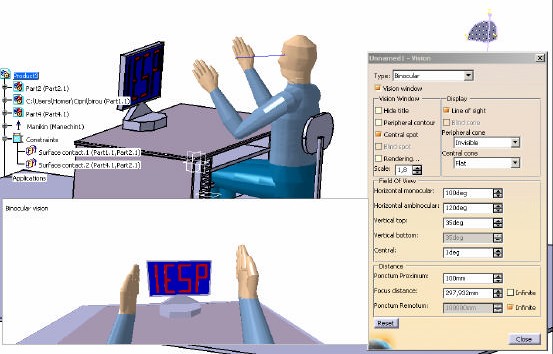

Finally, we present some results (figure 14 … 17) of our study and a short demonstration for the ergonomic design process for an office desk where the human operator has to sit and to develop his work duties using a computer.

Figure 14. The desk office design

Figure 15. The office desk, the chair, the flour and the manikin work position

Figure 16. The monitor distance verification

Figure 17. The manikin’s vision – visual ergonomics design

The Ergonomics Design and Analysis module from CATIA V5 is a very useful visual tool that brings time and money majors economy in the product design process.

REFERENCES

[1] Babur, M., P., Alexander, D., C., Industrial Ergonomics Case Studies, Barnes and Noble, Anglia, 1991

[2] Corlett, J., N., Clark, T., S., The Ergonomics of Workspace and Machines (a design manual), Barnes and Noble, Anglia 1995

[3] Draghici, A, Man- machine system re-design from the ergonomics perspective. A new methodology for production system optimisation, in: Methods and Tools for Co-operative and Integrated Design, Ed. Tichkiewitch, S. and Brissaud, D.,

Kluwer Academic Publishers Netherlands, 2003, Part 1(2), pg. 45-56

[4] Draghici, A., Nitulescu, M., and Mocan, M., Ergonomics Design and Analysis Using CATIA V5, Annals of the Oradea University, Romania, Fascicle of Management and Technological Engineering, CD- ROM Edition, vol. II (XII), 2004 [5] Jagdev, H., S., Brennan, A., Browne, J., 2004, Strategic Decision-Making in

Modern Manufacturing, Kluwer Academic Publishers, Boston, USA

[6] Nitulescu, M. and Draghici, A., Human Interface Optimisation Using an Ergonomics Design and Analysis Methodology, International Conference on Manufacturing and Management in 21st Century, Ohrid, Macedonia, CD- ROMversion, 2004

[7] Petiot, J.-F., Yannou, B., 2003, How to Comprehend and Assess Product Semantics – A Proposal for an Integrated Methodology, International Conference on Engineering Design, ICED 2003, Stockholm, Sweden

[8] Shneiderman, B., 1992. Designin g the user interface: Strategies for effectivehuman-computer interaction, 2nd ed., Reading, MA: Addison-Wesley

[9] Yannou, B., Petiot, J.-F., 2002, Needs, Perceptions, Functions and Products: highlight on promising design methods linking them, The 4th IDMME’2002,

Clermont Ferrand, France

[10] http://www-306.ibm.com/software/applications/plm/catiav5/

[11] ISO 13407, standard - Human Centred Design Processes for Interactive Systems