Introduction

There are many occupational risk assessment methodologies. These methods are usually based on the use of checklists and generate a numerical value for each risk. Also, these values are not in the same reference scale [1-5].

The implementation of a new safe strategy can involve the diminution of a particular risk and the increment of another. In this case, there is not any methodology capable of quantitatively assess if this new strategy would improve the global quality of the risk prevention in the occupational place.

The project object of this paper is focused to develop a new risk assessment methodology which allows quantify the quality of the risk prevention in an objectively way.

The proposed methodology is based on the similarities that can be found between environmental assessments and risk assessments. In this sense, the environmental assessment system developed at Battelle-Columbus Laboratories [6] has been taken as a model.

Methodology

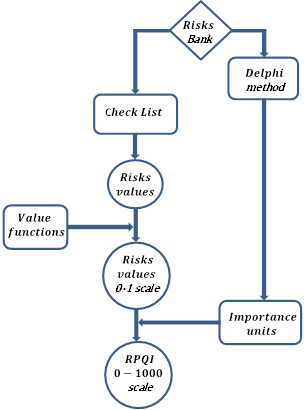

The flow diagram of the proposed methodology is shown in the Figure 1.

Figure 1. Flow diagram of the RPQI methodology

After making a check list, each of the obtained risks values is converted into common units by means of a specific "value function." After the value function application, all risks values are between 0 and 1. A value of 0 indicates very poor prevention quality, while 1 indicates very good quality. After this, risks are pondered through the assignment of importance units. Delphi statistic method would be used to assignment of importance units by independent expert groups to each risk. Finally, the Risk Prevention Quality Index (RPQI) between 0 and 1000 is obtained.

This methodology would be implemented by developing a software product structured as follow:

- Checklist

- Assignation of the Units of Preventive Importance (UPI). Based on the collection of informed judgments from experts in order to employ the Delphi technique

- Application of the value functions, f(Ri), defined with the aim to quantify the prevention quality for different risks.

- Calculation of the Risk Prevention Quality Index (RPQI).

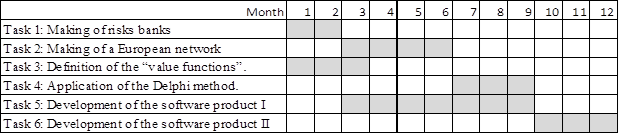

The expected project duration is 12 months. Figure 1 shows the provisionally schedule of the project.

Figure 2. Provisionally schedule of the project

Each of the project tasks are described below:

Task 1: Making of risks banks

This task consists in the elaboration of the base of the future libraries of risks in the software product.

Task 2: Making of a European network

The assignment of UPIs to each risk by independent expert groups is a crucial step in the development process of this quantitative methodology. In this sense, the objective of this task is the creation of experts groups for the different occupational areas and professional sectors.

Task 3: Definition of the “value functions”

Because the value of each of the risks is expressed in different scales, the value functions, f(Ri), must be defined. Statistic methodologies will be employed to define the f(Ri) functions to obtain risks values between 0 and 1 from the risk values obtained from standard methods.

Task 4: Application of the Delphi method

The main objective of this task is the assignment of the UPIs to each risk by the experts groups of the European network. Taken the Battelle-Columbus methodology as model, Delphi method will be employed. Also, “value functions” will be checked by the experts groups.

Task 5: Development of the software product I

In this task, the implementation of the risks banks, values of UPIs and “value functions” in the software will be carried out.

Task 6: Development of the software product II

The design of a commercial interface as the Final product is the objective of this last task.

Expected results

The Battelle-Columbus methodology has been successfully implemented in the environment ambit. Taking into consideration the similarities that can be found between environmental assessments and risk assessments, this project could be successful with a high percent of probability.

Financial support has been requested through the 2013 SAF€RA joint call on Human and organizational factors including the value of industrial safety.

Conclusions

The development of a software product within the methodology RPQI could be a commercial product with a high demand. Industrial firms could use it for improve or assess their safety management. Also could be an attractive product for external safety services. Furthermore, states can use this software for checking and characterize the quality of the risk prevention in different industrial areas or one occupational place in particular. On other hand, the RPQI could be used as a tool of giving information about the quality of the risk prevention in some occupational place to the workers, population or public administrations.

The success of this project could involve an improvement of the management of safety (1) providing a new tool for regulation in the policy framework and allowing to (2) quantify the effect on safety of new strategies as the resilience engineering approaches. Also it could allow getting a value useful for an (3) easier public access to information on safety management methods implemented by firms.

Acknowledgment

The author participation in the ORPconference 2014 has been supported by the Chair in Occupational Risk Prevention of the University of Seville.

References

- 1. Sousa et al.; 2008; Aplicación de métodos simplificados de evaluación del riesgo químico con efectos para la salud; Seguridad y Salud en el trabajo, nº 50, p. 2839.

- 2. Rubio Romero, J.C.; 2006; Métodos de evaluación de riesgos laborales; Ediciones Díaz de Santos.

- 3. Moreno Hurtado, J.J. et al; 2003; Manual de evaluación de riesgos, 2ªEd; Dirección General de Trabajo y Seguridad Social, Junta de Andalucía.

- 4. Martínez García, F.; 1990; “Sistemas de evaluación y propuesta del tratamiento de riesgos: SEPTRI”. Gerencia de riesgos, nº 29, p. 1921

- 5. Instituto Nacional de Seguridad e Higiene en el Trabajo: http://www.insht.es

- 6. Battelle Memorial Institute: http://www.batelle.org

Papers relacionados