Ferraço Jr., Darcy

Research and Development Center (CENPES)Av. Horácio Macedo, 950 / 21.941.915 - Cidade Universitária - Rio de Janeiro / Brasil+55 21 38 65 70 07 / darcyjunior@petrobras.com.br

Bobsin, Marco Aurélio

Research and Development Center (CENPES)Av. Horácio Macedo, 950 / 21.941.915 - Cidade Universitária - Rio de Janeiro / Brasil+55 21 38 65 20 53 / bobsin@petrobras.com.br

De Araújo, Mirian Peres

Research and Development Center (CENPES)Av. Horácio Macedo, 950 / 21.941.915 - Cidade Universitária - Rio de Janeiro / Brasil+55 21 38 65 75 25 / mirian@petrobras.com.br

Cabral, Simone Dias

Research and Development Center (CENPES)Av. Horácio Macedo, 950 / 21.941.915 - Cidade Universitária - Rio de Janeiro / Brasil+55 21 38 65 48 04 / simone.cabral@petrobras.com.br

ABSTRACT

ABSTRACT

The risk management has been processing in an evolutionary form through the years. Derived from military development, nowadays it encircles the industries and constitutes in one of the administration elements of large and medium corporations. At the Centro de Pesquisas Leopoldo Miguez de Mello (CENPES) the matter of risk management has passed through an expressive change with the implementation of the toll of the raising of aspects and impacts (Levantamento de Aspectos e Impactos – LAI) and the utilization of the risk factor as indicator of the risk administration in the managements of the research center.

Key words

Key words

Risk factor, risk management, risk analysis

INTRODUCTION

INTRODUCTION

The potential to an occurrence of big industrial accidents emerge with the proper developing process of new production technology. During the last three decades, the 100 major accidents in the installation of chemical processing and hydrocarbon several have injured or killed hundreds of people, contaminated the environment and caused losses of more than eight billion dollars to properties [1] [2]. The real cost of those accidents was much bigger owing to the fact of the existence of costs associated to the production paralyzation, business interruption, juridical costs, fines and market losses.

Therefore the contexture of accidents and their causes should be intrinsically related to preventing possibility [3]. Preventing such accidents is vital and implies in the development of systems of safe work.

In this scenery, the risk management has been an important factor of preoccupation and challenge to the industry and society in the last decades. This has been motivated as for the exigence imposed by society in relation to the safety of people involved, patrimony and to the environment preservation as well as the efficiency improvement, production and competitiveness in industry.

Risk analyze techniques have shown a powerful instrument to the outcomeof managerial decisions. Those techniques help the management of activities related to the project life cycle, allowing the politics implementation that minimize the operation costs, maintenance and inspection of industrial systems, retaining the safety levels demanded by society, as on the choice of the best option of the configuration of a project by the time of this acquisition.

The most habitual risk analyze techniques perform judicious uprising of theinstallation risks, without integrating the lifting to the work process, nevertheless the risk management in companies to be effective should attend the methodology development that promote the integration of the analysis process and risk evaluation with work process [3].

At Centro de Pesquisa Leopodo Miguez de Mello (CENPES) of Petróleo Brasileiro S.A. (PETROBRAS) the question of risk management passed by an expressive change with the implementation of the toll aspects uprising and impacts (Levantamento de Aspectos e Impactos - LAI) and the utilization of the risk factor as risk administration indicator in the research center management.

That administration model structured and developed necessary actions fordanger identification and evaluation of the risks pertaining to activities and operations of its process and installation with the aim of preventing from the occurrence of unwilling events and the minimizations of their consequences.

A new toll has been introduced in a way of prioritize indicator called riskfactor (Fator de Risco – FR), enabling the risk management existing in processes and activities.

Besides that, the work utilizes a tool to analyze the risks, through the inclusion of parameters like: the existence of risk control in order to evaluate the frequency and the damage dimension, to evaluate the risk severity, permitting a better evaluation criterion of the identified risks.

HISTORIC AND INSTALLATION DESCRIPTION

In the 50-decade the research activities of PETROBRAS were concentrated in mind the national politics of importation substitution and the necessity of the installation of the refine Brazilian park.

In 1963, CENPES was created, an entity exclusively focused on activities ofresearch, development and institutional coordination of PETROBRAS technologies.

In 1975, it was given the name which it is know nowadays – Centro de Pesquisas e Desenvolvimento Leopoldo Américo Miguez de Mello (CENPES).

The researches performed by CENPES are internationally recognized and they place Brazil among high technology withholder countries in petroleum industry.

CENPES owns 45,000 m2 constructed area and 137 laboratories developingresearches in the submarine technology area, environmental monitoring, combustibles development, renewable energies, etc.

It constitutes a modern installation that houses approximately 4,200 workers, it possesses 22 buildings and tank park for the storage of inflammables and combustibles, according to picture 1.

Picture 1: Aerial view of CENPES

METHODOLOGY

The major preoccupation of the risk system administration is to lessen or eliminate the occurrence of unwilling events, increase the ways of control so that they do not happen and to have detection means capable of signalizing to the system certain situation in order to have a quick response.

Basically, the risk analysis methodology consists in answering the followingquestions Kletz [4] related to the study matter: 1- What can go wrong?2- How often can it occur?3- What are the consequences?

In that case, to start a process of taking a decision utilizing a risk analysis we can face another bigger problem. The quantity of risk that involves three major elements that include: dangerous scenery, occurrence probability and severity consequence.

To turn the evaluation and classification less subjective, we have introduced some variable options to those factors, giving more technical consistency to the evaluations. Besides that, this concept means a more efficient dealing over the danger prevention, instead of only putting into action the protection forms.

Aspects and impacts uprising

The methodology of identification of aspects/dangers and impacts/damages utilized by CENPES has as reference the precepts exposed on normative requisites of OHSAS 18001:1999 [5], ISO 14001:2004 [6] and on the corporative requisites of politics and security directing, PETROBRAS environment and Health.

Initially were identified the aspects/dangers in stages that involved theconstruction of the main administration in a way of identifying the tasks, processes and developed critical activities. This structure facilitated the construction of data bank that contains all elements of the risk management.

The identification of aspects/dangers and impacts/damages was done through interviews and execution observation taking as a base of the standard of the execution of the tasks and their flux. This identification was owed to different work groups, however adopting a pattern description to the aspects/dangers and impacts/damages in order to facilitate the uprising, to equalize the result.

In the built main administration and to make possible the creation of basic schedule, that generated a corporative program designated safety, environment and health (SMSNet).

Risks classification

According to what was previously described, to turn the risk evaluation and classification less subjective, we introduced some options to these factors, giving more technical consistency to evaluations.

That way, new options were included which act on the occurrence probability: efficiency on the control and detection level. Moreover, there is the occurrence frequency (or the danger exposure level).

Probability = Frequency + Control + Detection

When we want to increase the protection means, it signifies that, besides trying to diminish the impact severity, we should proceed over its encircling scale, or to make the impact extension as minor as possible. That way, it was introduce the concept of the failure effect that considers these two aspects together: the effect severity and its damage extension.

Failure Effect = Severity + Encircling Level

For that reason, the risk definitions can be described the following way: Risk = Probability (F+C+D) x Failure Effect (S+A)

|

|

F= Frequency S= Severity C= Control A= Encircling Level D= Detection |

The methodology was developed having as a reference the criteria described in the aspects and impacts uprising (LAI) and the methodology of the risk administration system construction.

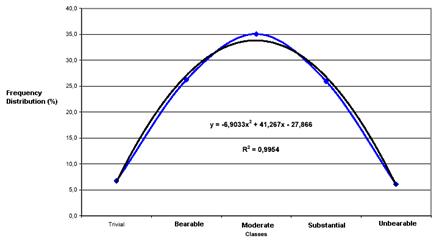

On the classification of the risk significance five risk levels were stipulated: trivial, bearable, moderate, substantial and unbearable, nevertheless the cogitation factors for the risk matrix may vary in function of the reality of each company or installation.

Risk matrix calibration

In order to obtain an adequate mathematical model, the adjustment criterion looked for class distribution and ponderers that when adopted, would result in a polynomial curve of second potency, it means, a binomial curve of probability distribution on risk classes mentioned in figure 2.

Figure 2 – Frequency distribution

For the alternative that presented the values that adapted the most to CENPES risks, classification and evaluation system, ponderers described in schedule 1 were utilized.

Schedule 1: Risk matrix

CENPES adopts as significative the risks classified as moderate, substantial and unbearable, although, it is necessary to consider that significance is not permanent, but circumstantial.

Risk factor

To each risk category it is associated a risk score or a numerical factor that is used for the risk calculi. According to schedule 2, it is observed that the cogitation grows meanwhile the risk category is becoming more critical.

There are two more types of score: actual score and pattern score. Theactual score relates the real system situation. In mathematical terms it is summational the product among identified number of events (aspects/dangers) in each risk category, with its risk associated score. On the other hand the pattern score represents a desirable situation to the system, or the high administration defines the acceptable risk degree for the system.

The risk factor is determined through the division between the actual score and the pattern score. The excellent system condition is to reach the risk factor equals to 1 (one). This way, factors above 1 (one) indicate that the risks still need to be treated to reach an established condition by the risk administration system for that process/activity.

For example, in a certain process 11 events were registered this wayidentified: six trivial one, two tolerate ones, two moderate ones a substantial one. The actual score is calculated through the addition of the products of actual risks, it means, 1226 = 6x1 + 2x10 + 2x100 + 1x100.

In this case, the high administration determined that all risks would betaken, in the maximum, to the bearable category. So, the number of registers (events) of the other categories moderate and substantial were added to the number of registers classified as bearable and multiplied by the risk score o f the bearable category, to determine the pattern score.

The final calculus of the pattern score is the addition of the product among the number of events (aspects/dangers) considering just the cogitation referring to the score trivial and bearable (1 and to 10). In this case, pattern score would be 56.

As for the risk factor calculus, we have the value of 21.89 (1226/56), what means that this process is bellow what was expected in relation to the risks, therefore, far from the ideal situation.

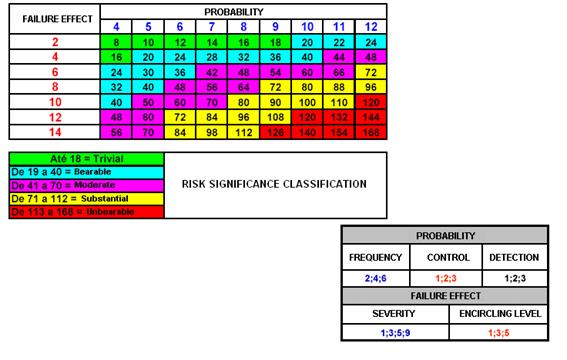

RISK ADMINISTRATION PROCESS

The first step to the risk evaluation and administration is the uprising, according OHSAS 18001 [5] and ISO 14001 [6], of aspects and impacts in the installations, processes, task and activities of unit. This uprising can come from the most complex risk analysis studies, for example: QRA – Quantitative Risk Analysis.

Previously, a risk evaluation is done through structured techniques accordingto a methodology presented on previous item, classifying them in 5 classes in relation to the significance, no matter what: trivial, bearable, moderate, substantial, unbearable.

The data consolidated on the SMSNet system where the identified risk canbe consulted by all work force.

On the next stage, utilizing the criteria of risk tolerance a based on the risk factor, are prioritized the risk for measure control application. From that stage on, action plans are elaborated, administered the implementation of recommendation and achieved the critical process analysis. The following figure 3 presents the summary of this process.

Figure 3 – Risk administration process

SMSNet system

The SMSNet System (figure 4) is an essential tool for the risk administration, once it centralizes all registers referring to the aspects and impacts uprising of all CENPES processes, activities and installations. It is also an interface among all management departments and the safety management, environment and health (SMS) in a way to establish an efficient and quick communication for monitoring, treating and controlling identified dangers/risk.

Figure 4 – SMSNet

Risk factor

The system permits that a decision be taken, utilizing the risk factor, creating a possibility of managing the existent risks in the processes and of the management activities in a selective form.

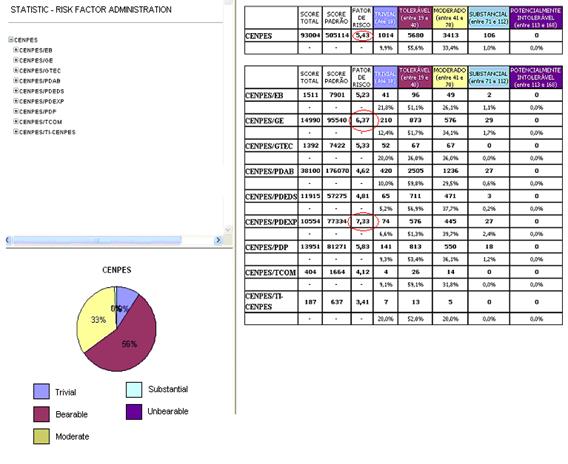

The pieces of information are consolidated in only one screen and arefurnished according to a managerial elaborated matrix, allowing this way a critical risk analysis, a comparison among the total of risks, and the managements, beside being used as a criterion of choice to manage the management risks. For example CENPES risk factor, according to figure 5 is 5.43, being two managements (any of them) own a bigger risk factor, 7.33 and 6.37, respectively. This way, the risk factor turns into one of criteria to prioritize the implantation of control measures and risk reduction in these managements at CENPES.

Figure 5 – Risk Factor Administration – comparison among managements

CONCLUSION

The calculus of the risk factor came to help the identified managerial risk process turning it simpler and at the same time reliable, as the pieces of information are originated in the uprising of aspects and impacts belonging to the SMSNet program.

The inclusion of diversified levels for the identified risks and the risk factorhelps the administrators during the process priority on the control of these risks, being a useful criterion to the definition of the measures to be implanted.

For this reason the risk factor is an important tool on the identification andselection of activities that need the intervention in order to reduce risks and implantation of measures of control to avoid accidents, incidents, deviation, as well as minimize its impacts

Its operating is simple and its database is assessable from the executivemanagement to the individual level of each employee. So, anyone can have access to the risks of the managements, from the locals to the activities making it know not only the risks that the person is exposed, but also the ones from other place.

The cost of the development and implantation is very reduced and therelation cost/benefit is minimum falling the benefits mentioned. Beside that the system implantation is done in a very fast way.

Seeking for excellence in SMS, the company makes use of efficientresources in order to avoid the occurrence of damaging events to the workers and the environment. With the development of this work, we could confirm that the SMSNet is a tool that by its means the work force is informed about the risks that can originate at work places and the means used to control such risks and measure adopted by the company.

REFERENCES

- 1. J.C Coco, ed., Large Property Damage Losses in the HydrocarbonChemical Industries: A Thirty Year Review, Eighteenth Edition, Marsh and Mclennan Protection Consultants, Chicago, IL, 1998.

- 2. The Phillips 66 Company Houston Chemical Complex Explosion and Fire, Occupational Safety and Health Administration, U.S. Department of Labor Washington, DC, April 1990.

- 3. BENITE, Anderson Glauco. Sistemas de Gestão da Segurança e Saúde no Trabalho. São Paulo: O Nome da Rosa, 2004.

- 4. KLETZ, Trevor. A., What Went Wrong?; Case Histories of Process Plant Disasters, Gulf Publishing Company, ISBN 0872013391, 1985.

- 5. BRITISH STANDARDS INSTITUTION – BSI. Occupational health and safety management systems – specification OHSAS 18001:1999, London, 1999. 16p.

- 6. ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS – ABNT, Sistema de gestão

ambiental – Especificação para uso – NBR ISO 14001:2004, Rio de Janeiro, 2004. 14p.

Papers relacionados