Introduction

Since the dawn of the industry, the man begins to work, until today, the desire for preservation and fear of injury is an ever-present feature. For this reason it has always practiced some form of prevention, which has been improving over the years supported by several laws, aimed at improving the overall health of people in the workplace.

When talking about the health of workers, keep in mind that alterations of the same are given by two different pathologies, specific and nonspecific. The first occurs in the direct relationship between work and injury or functional alterations of the worker, which are work accidents and occupational diseases. While the second is that cannot directly relate to working conditions [1]. This difference tells us that a worker is affected not only by the working conditions, but also by the environmental conditions in which they live and develops its activities outside work.

The Noise

There are several dangers to which a worker can be exposed both in the workplace and at home and therefore each one of them deserves a particular analysis. In the present investigation performed an analysis of one of the dangers present in both industry and residential area, which is noise.

Acoustically, noise is defined as the power output caused by vibratory motion which is detected by the ear of a person which can cause a feeling of discomfort or even pain [2]. It is an unwanted sound, inarticulate and confused more or less strong.

Noise is one of the physical aggressor with whom one lives and which is continuously growing. It is a problem with difficult solution because they are many and scattered emission points [3].

Generally the noise was always a labor problem, affecting operators who are in their turn exposed to noise of a machine or tool that works as part of the task at work. However, modern civilization is exposed to noise in the streets, parks, supermarkets and even at home.

Depending on the context in which it operates, it can be classified as industrial noise and urban or environment. Thus, the first case refers to hearing loss, noise trauma and damage that occurs during labor activity in the workplace, while the environment is generated great deal of noise levels produced by daily emission sources as ground transport, electrical appliances and entertainment centers issued.

The possibility of harm as a result of noise, will be a function of the received dose, which is given by the accumulation of sound energy along the length of exposure. This dose, is associated by the concept of Equivalent Continuous Sound Level (Leq), which represents an average value of noise during the exposure time [4]. The main effect of noise is decreased hearing ability. Because of its slow and gradual onset, hearing loss is not perceived by people. It is difficult to distinguish between hearing loss due to age and working conditions [5], which is why hearing loss records reported to the Superintendency of Occupational Risks in recent years are very low, (1 case of hearing loss per year) for the province of Misiones [6].

But the noise acts not only in physical appearance, but also influences the intellectual aspect, mainly in the attention span, reducing the individual's work performance, both intellectual and physical [7].

The town or city noise does not typically produce hearing loss, unless the level is very high and for a long period of time, however, a high noise level can generate sleep disturbances arising in other conditions. A level above 42 dB noise can cause disruption of nocturnal sleep. According to studies conducted, the average time that a normal adult person is in bed is 7.5 hours, but the average sleep time is much shorter [5].

Oberá is no stranger to the noise problem. Its population density is in the second most populous city of Misiones province, which brings about the existence of numerous noise sources arising from this high urbanization, such as transport of varying amounts (buses, trucks, cars, motorcycles), proximity to national and provincial roads, streets and busy avenues, construction sites, transformers stations, etc.. Added to that, it should be considered the presence of a large number of industries in different products (tea, yerba, wood, among the main) that are located both inside and outside the urban area.

Industries that are in the area include the timber sector as one of the main items contributing to the economic sector, allowing for a good amount of small and medium enterprises engaged in sawing wood. In this industry, the use of many machines needed for woodworking such as sawing, debarking, pruning, transport, etc., determines the presence of dangerous noise levels that exceed recommended by law. Noise is mainly generated by the contact between the saws and the work material, which make difficult to reduce since it is a core activity for the process.

The overall objective of the study is to determine whether a timber industry worker of township Oberá are subject to noise levels which exceed the limits established by current legislation, both in the workplace and in their residence area and make proposals to improve in if necessary.

Identification of the Industry

The industry selected to carry out the analysis is a renowned company in the city of Oberá. It is dedicated to forestry, typically aimed at sawmilling implanted and native forest as the main activity, continuing their value chain by producing crosspieces roofing, floor preparation, and ceiling coverings (machimbres), cornices, valances , Cairns, all of various sizes.

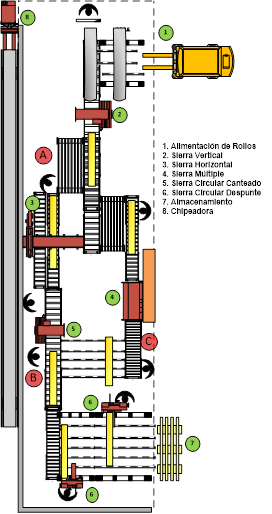

The company has two plants, one for sawing the implanted forest and other for sawing wood of native forest. These two sectors should be added one more that corresponds to Tongue and groove (manufacture of coatings and ceilings). Figure 1 shows the physical layout of the different sectors within the industry analyzed is indicated.

Figure 1. Distribution of the different sectors of the sawmill

Identification of the area of residence of operators

Identifying the areas of residence of workers was conducted through a survey where the same data were asked about their home.

Notably, 80% of the workers of the firm is located within 400 meters with respect to the company and the rest at a distance of between 1.5 and 2 km. The area where most of the workers is considered a residential area with homes of middle and lower class. The streets are cobbled or terrades. The vehicular traffic is not very common, except the street where the plant is, which is usually the busiest route by flowing even urban buses is located. The analyzed company is the only industry in the area. The neighborhood also has a primary school.

As for the workers who are further away from the industry, their location has similar characteristics to the above, except for one that resides on one of the main avenues of access to the city, which is characterized by fluid transit of different sized vehicles.

Methodology

Assessment of Occupational Noise

As a first step to carry out the study, existing positions in each of these sectors work were identified. The activities carried out in each sector are similar since they consist essentially in sawing and transporting timber across sectors and to the store.

At each noise measurement was performed using an integrating sound level meter Type 2 complies with the rule IEC61672-1, accuracy + 1.4dB and operates in a frequency range of 31.5 Hz - 8KHz.

The following recommendations were followed for the measurement:

- Check the measuring equipment, battery status and calibration of equipment, both at the beginning and end of the measurement.

- The sound level meter is installed in the place normally occupied by the operator, but trying to keep it away from the body to prevent wave reflection and concentration. This requires a tripod on which the meter is placed in use.

- The sound level meter at ear level of the people is placed, the type of response and attenuation is selected.

- With the recorded values given by the decision No. 85 of 2012 of the Superintendency of Occupational Risks is full, allowing comparison with the maximum level permitted by current legislation table.

Comparing the results with the normalized value, determined if the permitted levels are exceeded and accordingly the level of risk was assessed following the methodology of evaluation given by the IRAM 3801, which proposes a level estimator risk given by table 1.

|

Severity Probability |

Slightly Harmful |

Harmful |

Extremely Harmful |

|

Very unlikely |

No significant risk |

Insignificant Risk |

Moderate Risk |

|

Unlikely |

Insignificant Risk |

Moderate Risk |

Significant Risk |

|

Likely |

Moderate Risk |

Significant Risk |

Intolerable Risk |

Table 1. Simple Estimator Risk Level.

Depending on the level of risk suggested corrections to reduce the levels of noise are performed.

Evaluation of Urban Noise

Based on the identification of the portions of residence of operators, a classification based on zoning proposed IRAM 4062, which is indicated in Table 2 is performed.

|

Operario |

Location |

Type |

Zone |

|

Operator 1 |

Avenida Inmigrante |

4 |

Urban residential with some light industry |

|

Operator 2 |

Almirante Brown |

3 |

Urban residential |

|

Operator 3 |

Fray Justo María de Oro |

3 |

Urban residential |

|

Operator 4 |

Lago Deseado |

3 |

Urban residential |

|

Operator 5 |

Paraguay |

3 |

Urban residential |

|

Operator 6 |

Río Cuarto |

5 |

Commercial or Industrial Intermediate Center |

|

Operator 7 |

Trenque Lauken |

2 |

Suburban with little traffic |

Table 2. Classification of areas of residence of workers.

At each location noise measurements were performed following the procedure laid down in that IRAM 4062.

Given that for the study of particular interest is the noise that exposed the operator in place of residence times considered for the analysis includes labor extra, from 12hs to 14hs and 19hs to 6 hours.

The measurement was made using a different sampling in the selected measurement points during an observation period of 2 months. In addition, samples were taken at regular working days (will not consider weekends and holidays) and in which environmental conditions were similar, this in order to obtain results that are comparable. The measurement included at least one cycle of the noise characteristic. For highly variable noise, times the worst noise were selected.

The levels of reference or comparison (Lc) were determined according to the provisions of the IRAM 4062, which sets limits for noise is considered Annoyed (Leq - Lk> 8dBA), or Not Bothered (Leq - Luke <8dBA). The recommended limit values also correspond to the ISO 1996 standard, which sets a limit of 55 dBA for the day and to 45 dBA for night in urban housing areas, while for the shopping area a level of 65dBA to 55 dBA for day and night respectively.

As a further assessment an analysis considering the regulations in the City of Buenos Aires has application where Act No. 1540 Decree No. 740 of Noise Pollution Control was performed. For application of it must have values of background noise (Lf), which is the sound pressure level that can be measured when the source object of analysis or evaluation is not broadcasting and average noise level (lm), which is the average Leq measured at three different sites, three times for 5 minutes minimum. Using these values, the noise level is calculated to be considered (Le) [8].

The value obtained should be contrasted with the maximum corresponding to each zone, which is set in a table of the Act. In addition, you must meet the calculated value is less than the background noise plus seven dBA.

According to the results obtained recommendations to be considered by operators to avoid exposure to noise pollution in their residence area were performed.

Results

Industrial Noise

The values obtained in each of the jobs, as well as the maximum allowed limit for the day indicated in Table 3.

|

MEASUREMENT DATA |

||||||||

|

Id. |

Sector |

Workstation |

Exp. (Hs.) |

Meas. (Min.) |

Noise |

Values |

Comply? (YES / NO) |

|

|

Leq (dBA) |

Limite Value |

|||||||

|

1 |

S. Black Forest |

Court in Horizontal Saw |

8 |

120 |

Intermittent |

86,87 |

85 |

NO |

|

2 |

S. Black Forest |

Canteado |

8 |

20 |

Intermittent |

94,92 |

85 |

NO |

|

3 |

S. Black Forest |

Pinch |

8 |

15 |

Intermittent |

90,15 |

85 |

NO |

|

1 |

S. Machimbrado |

Machimbradora |

8 |

15 |

Continuous |

93,6 |

85 |

NO |

|

2 |

S. Machimbrado |

Pinch and Classification |

8 |

15 |

Continuous |

94,23 |

85 |

NO |

|

3 |

S. Machimbrado |

Armed with Bales |

8 |

15 |

Continuous |

86,83 |

85 |

NO |

|

1 |

S. Implanted forest |

Court in Twin |

8 |

15 |

Continuous |

89,1 |

85 |

NO |

|

2 |

S. Implanted forest |

Horizontal Saw Output |

8 |

20 |

Continuous |

92,68 |

85 |

NO |

|

3 |

S. Implanted forest |

Horizontal Saw Alimentation |

8 |

40 |

Continuous |

90,87 |

85 |

NO |

|

4 |

S. Implanted forest |

Múltiple Saw and Canteado |

8 |

20 |

Intermittent |

94,56 |

85 |

NO |

|

5 |

S. Implanted forest |

Pinch |

8 |

15 |

Intermittent |

87,84 |

85 |

NO |

Table 3. Noise measurement data at the mill.

The results show that the maximum permitted levels for the work period are exceeded. Depending on the level of risk it is analyzed. According to the classification given by the IRAM 3801, the damage can be considered intermediate, this depending on the levels exceed the standard and the most likely result is deafness, and other physical or psychological effects.

Regarding the likelihood of injury, it should be noted that while all workers are exposed to noise in their jobs, they mostly have personal protection (protective cup or endoaurales). Based on this an unlikely risk is determined.

Having considered the seriousness of the risk as an intermediate, ie harmful, and an average probability, that is unlikely, a Moderate Risk is obtained. For this level of risk it states that ¨ Standard precautions should be taken to reduce risk. Should be implemented risk reduction measures within a defined period ¨ [9].

Environmental noise

Table 4 shows the noise levels obtained the respective indicated for different measurement periods, as well as you can see the equivalent continuous sound level (Leq) for the day and night (in the times mentioned above) and maximum values, which are corrected uncertainty values recommended in the IRAM 4113-2.

|

Measurement |

Calculated level |

Results |

|||||||

|

Location |

Leq day |

Leq night |

Lmax day |

Lmax night |

Day |

Night |

Day |

Night |

|

|

Avenida Inmigrante |

70,2 |

60,29 |

88,1 |

72 |

55 |

45 |

ANNOYING |

ANNOYING |

|

|

Almirante Brown |

57,61 |

47,9 |

76,7 |

44 |

50 |

40 |

NO ANNOYING |

NO ANNOYING |

|

|

Fray Justo M. de Oro |

56,48 |

62,4 |

80,4 |

83,5 |

50 |

40 |

NO ANNOYING |

ANNOYING |

|

|

Lago Deseado |

56,8 |

47,12 |

76,7 |

53 |

50 |

40 |

NO ANNOYING |

NO ANNOYING |

|

|

Paraguay |

63,33 |

46,58 |

86,6 |

54,9 |

50 |

40 |

ANNOYING |

NO ANNOYING |

|

|

Río Cuarto |

60,01 |

49,39 |

79 |

54,3 |

60 |

50 |

NO ANNOYING |

NO ANNOYING |

|

|

Trenque Lauken |

48,12 |

36,8 |

48,7 |

41 |

45 |

35 |

NO ANNOYING |

NO ANNOYING |

|

Table 4. Measurements of ambient noise.

The data obtained show the coincidence as annoying Avenue Immigrant industry, which is one of the main arteries into the city. In addition, two other streets are annoying, one during the day Paraguay street and overnight, Fray Justo indicated.

Following the rules in force in the Autonomous City of Buenos Aires the data obtained are shown in Tables 5 and 6.

|

Location |

Lf |

Lm |

Le |

Normalized |

Satisfy |

Lf+7 |

Satisfy |

|

Avenida Inmigrante |

49 |

59 |

59 |

55 |

NO |

56 |

NO |

|

Almirante Brown |

42,5 |

45 |

41,41 |

50 |

YES |

49,5 |

YES |

|

Fray Justo María de Oro |

42 |

48,5 |

47,40 |

50 |

YES |

49 |

YES |

|

Lago Deseado |

42,5 |

45 |

41,41 |

50 |

YES |

49,5 |

YES |

|

Paraguay |

39,6 |

45 |

43,52 |

50 |

YES |

46,6 |

YES |

|

Río Cuarto |

46,4 |

49,4 |

46,38 |

50 |

YES |

53,4 |

YES |

|

Trenque Lauken |

37 |

44 |

43,03 |

50 |

YES |

44 |

YES |

Table 5. Daytime noise measurements. Pursuant to Law Decree 740 1540

|

Location |

Lf |

Lm |

Le |

Normalized |

Satisfy |

Lf+7 |

Satisfy |

|

Avenida Inmigrante |

39 |

44 |

42,35 |

45 |

YES |

46 |

YES |

|

Almirante Brown |

37 |

41 |

38,80 |

40 |

YES |

44 |

YES |

|

Fray Justo María de Oro |

41 |

42,5 |

37,15 |

40 |

YES |

48 |

YES |

|

Lago Deseado |

38 |

41,6 |

39,11 |

40 |

YES |

45 |

YES |

|

Paraguay |

33 |

41 |

40,25 |

40 |

YES |

40 |

YES |

|

Río Cuarto |

43 |

45,1 |

40,94 |

40 |

YES |

50 |

YES |

|

Trenque Lauken |

32 |

40 |

39,25 |

40 |

YES |

39 |

YES |

Table 6. Nighttime noise measurements. Pursuant to Law Decree 740 1540

The values obtained agree with the IRAM 4062 to identify Avenue Immigrant as Annoying sector.

Occupational Noise Correction

The optimal way to reduce exposure to noise is acting on the generating sources, ie the source of the noise. At work this is limited to the acquisition of machinery and tools that generate lower noise emissions [10]. While this may be achieved by a careful selection of team, to have the desired effect, must be accompanied by an adequate statement of use by manufacturers, and an analysis of the physical layout of the various facilities that make the production process, by employers.

In this case the proposed amendment raises performance measures from three points of view, on the source of the propagation medium and the receptor or operator.

Correction Source

Noises generated at the source are mainly due to contact between the material and the mountains of work teams. To reduce noise must be used together insulating and absorbent material, since with them by friction energy is eliminated and the noise level [2] is reduced.

For a material is absorbent must be porous, with open pores and interconnected, so as to allow the passage of air vibrating (sound) and with varying degrees of difficulty, to pass from one side to another, losing sound energy in this effort . By contrast, an insulating material generates a physical barrier between the place where the sound is emitted and received it, producing a sound reflection of the incident, which reduces the noise level to the recipient.

|

insulating Material, eg: Concrete |

Absorbent material, eg foam |

Combination Absorbent and Insulating Material |

|

|

|

|

Figure 2. Effects absorbent insulating material. [11]

Some of the proposals to reduce noise in the equipment are set out below

Circular Saws: The noise originates from these computers can usually be caused by vibration and resonance radiation and leaf material being cut. When a material is sawn, saw the movement is transmitted to the piece you are working and producing exciting resonance noise. The mechanical resonances amplify the noise emitted, so adding a buffer in the saw blade assembly rigidity is increased and noise is reduced by having transferred to another resonance highest frequency [12].

The resonance can be reduced if it is placed on each side of the saw disc about three millimeters in thickness of a viscoelastic material such as high performance polyurethane or rubber, which covers at least 30% of the surface of sheet, compressed in turn by another metal disc of the same diameter as the former. This combination of materials adds mass and stiffness, which reduces the amplitude of the resonance.

![]()

Figure 3. Reduced resonance in Circular Saw

In turn, to reduce the noise emitted by the saw material contacting a combination of absorbent insulating material is placed.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Figure 4. Thumbnail absorbent insulating material in Circular Saw

The insulating material placed besides avoiding direct propagation of noise to the operator, this protects from accidental contact with the saw which would cause a cut or amputation, while avoiding the flying particles and dust.

![]() For the rest of the teams sawmill cutting a combination of absorbent insulating material and allow full use of the equipment enclosure. The materials used are mainly wood and FONAC 50mm. For the inlet and outlet of the material fixed rubber bands are used on top, which allows them to be driven by the same material in and out. Selected materials allow a reduction of approximately 15dBA noise emitted by the machine. Besides its cost is relatively low, mainly wood, which is a product that is abundant in industry analysis. Figure 5 shows one of the enclosures for the machine named Sierra Multiple

For the rest of the teams sawmill cutting a combination of absorbent insulating material and allow full use of the equipment enclosure. The materials used are mainly wood and FONAC 50mm. For the inlet and outlet of the material fixed rubber bands are used on top, which allows them to be driven by the same material in and out. Selected materials allow a reduction of approximately 15dBA noise emitted by the machine. Besides its cost is relatively low, mainly wood, which is a product that is abundant in industry analysis. Figure 5 shows one of the enclosures for the machine named Sierra Multiple

![]()

![]()

![]()

Figure 5. Thumbnail absorbent insulating material in the Sierra Multiple

Correction on the transmission medium

For this case it is proposed to carry out a plan redistribution of equipment to separate the set of machines that generate noise. The proposed redistribution arises for sawmilling sectors and implemented native forest, which has a higher concentration of machines.

Sawmilling Sector Native Forest: Amend the location of machines and establish a facility in line for the product from entering the supply ironed as roll, until it is removed from the tank as notcher to be a tight sequence of activities. The current distribution in the given plant and is shown in Figure 6. With this new distribution not only separated from each machines that generate more noise, but also the hand movements and heavy lifting done by the operators, reducing ergonomic risks associated with them are reduced. On the other hand it is also proposed to facilitate shipments of waste, conveyor belts have with them a common sector for storage and subsequent disposal. The new distribution reduces transit times and thus production capacity is also improved.

|

|

|

Figure 6. Actual and Proposal Lay-out Sawing Native Forest Sector

Implanted Sawmilling Forest Sector: With the redistribution proposed for this sector seeks to decentralize the number of machines that generate noise and away from the operators. The proposal is shown in Figure 7, where it is compared with the original distribution. In the red circle concentration of operators that are surrounded by machines that generate noise and that is the most affected sector currently stands. In the new distribution separation equipment plus redistribute operators and prevent them being surrounded by machines occurs. In the posts marked with the letters A, B and C ergonomic risk and forced movements are reduced, as are automated transport and prevents the operator must lift tables. As for waste collection focuses it toward the left side of the plant as it currently exist. The new layout also provides access to job sector operators, as in the original distribution should go over one of the machines to access their post.

|

|

|

Figure 6. Actual and Proposal Lay-out Sawmilling Forest Sector Implanted

Correction on the receiver

The correction on the receiver, in this case the operator, is to provide adequate protection to enable personnel lowering the noise level received by the same. Importantly, this is not the first step to take, nor recommended, however it is necessary to have personal protection for any residual risk exposure, having taken the measures proposed above.

For proper selection of personal safety, it is necessary that the measurement is made with a sound level meter with frequency analyzer, to identify the attenuation for each frequency. As in this case there is no such equipment, however an analysis of existing hearing protection is performed and can be applicable in these cases.

Of the different options, it is recommended the protector is reusable 3M EAR Ultrafit Earplugs. The criteria chosen to select this case is mainly based on cost-benefit and hygiene in handling the protective relationship, considering that the environment where tasks are performed is very exposed to the dust, sweat and other contaminants .

Discussion of results

The mean values show the existence of noise levels that exceed those allowed for a workday, and therefore may alter the hearing health of people, as well as other psychological and physiological changes. While sawmill owners know the issues, the immediate solution is always be providing hearing protection, which does not ensure adequate protection, since the frequencies are not considered for the selection thereof and continuous monitoring is not performed to check the use thereof by the operators.

Normally the noise inside a sawmill has values ranging between 87 and 100 dBA. However, a 1996 study revealed that operators of machinery are permanent sound waves located between 96 to 99 dBA. [13]

According to studies conducted in U.S. sawmills, 72.5% of workers evaluated had some degree of hearing impairment to one or more frequencies in the audiometric testing, which shows that workers in sawmills and other wood processing industries have high risk of hearing loss by noise. People working in the vicinity of saws and other machines woodworking are often exposed to over 90 or 95 dBA levels. Despite this well known risk, attempts to reduce noise levels are relatively low so that new cases continue to occur in noise-induced hearing loss [14].

According to those raised improvements is proposed as a first step to continue occupying hearing protectors as they have done so far as the operators of the equipment enclosure is made. Start the enclosure in machimbrado sector, with machimbradora and circular saws. Continue with the closing of the different machines in the native forest sector Sawing and finally make first proposed in the native forest sawmilling sector and then in the redistribution of planted forest.

It is recommended after narrow redistribution, calculate and design an extraction system suction machines to facilitate the collection of dust, chips and sawdust of the same, thus contributing to order cleaning, reducing the risk of fire and the accumulation of dust in absorbing materials installed, as well as the heat generated by the equipment.

Together with measures that will be incorporated, it must continue controls on existing noise levels after implementing some improvement as well as the hearing status of operators. It is also important to conduct periodic risk assessments to identify new hazards that may arise with the implementation of the proposed improvements.

Urban Noise Correction

According to the results obtained in measurements of urban noise, it can be seen that the most unfavorable condition is recorded in Immigrant Avenue, which is characterized by a high flow of vehicles varying amounts. While the recorded values do not represent a risk to hearing health of operator residing in this area, existing levels could influence proper rest of the person. It should be noted however, that the measurements were performed outside the operator home. In a normal building with brick walls and glass windows, acoustic insulation to consider may be 25 dB, which greatly reduces the measured values and can guarantee that the person on the premises not be affected by noise. To do this, be careful not to open doors and windows during the hours of rest.

Conclusions

The sawmill industry is one of the largest in the province of Misiones and well in the city of Oberá and as we noted the existing noise levels in the workplace outweigh the regulated. This situation shows that there is a high number of people every day are subjected to noise and their effects on health. However, by simple measures with relatively low costs and using materials that are present in all industries of this type, such as wood, can reduce levels of allowed values and considering the use of EPP as an additional measure, and not as the principal that is usually adopted in most cases.

While the study was oriented exclusively to noise, many of the proposed correction raised, can reduce the risk levels of more than one hazard, which is useful to justify the proposed measures always represent a cost to the employer.

As urban noise it was found that while most areas are not significantly affected by this pollutant, population growth and increased fleet begin to turn Oberá in a noisy area, such as in most large urban centers. In this regard it is important to further analyze the effect of noise in all times, considered all sources contributing to it. As already mentioned, with some simple steps can prevent the disruptive effects of noise in urban areas were more annoying.

Thanks

A preliminary version of this paper was presented at the ORP Conference 2014.

References

- 1. Creus Solé, Antonio y Mangosio, Jorge Enrique. Seguridad e Higiene en el Trabajo. Un enfoque integral. Buenos Aires, Argentina: Alfaomega, 2011. ISBN: 9789871609192.

- 2. Rejano de la Rosa, Manuel. Ruido Industrial y Urbano. Madrid, España: Paraninfo, 2000. ISBN: 8428326827.

- 3. Capó Martí, Miguel. Principios de Ecotoxicología. Diagnóstico Tratamiento y Gestión del Medio Ambiente. Madrid, España: Tebar, 2007. ISBN: 9788473602631.

- 4. Giménez de Paz, Juan. Ruido, Para los posgrados de higiene y seguridad industrial. Buenos Aires: Nobuko, 2007. ISBN: 9789875841055.

- 5. Bell, Alan y World Health Organization. El Ruido: Riesgo para la salud de los trabajadores y molestia para el público. s.l.: Ginebra: Organización Mundial de la Salud, 1969. ISSN: 924330030X.

- 6. Ministerio de Trabajo, Empleo y Seguridad Social. Superintendencia de Riesgos del Trabajo. Estadísticas de Accidentabilidad. Boletín anual por provincia. [En línea] 2011. [Citado el: 20 de Octubre de 2013.]http://www.srt.gob.ar/inicio/srt/contenidossrt/estadisticas/accidentabil....

- 7. Ganime, JF, y otros. El ruido como riesgo laboral: una revisión de la literatura. Murcia: Enfermería Global, 2010, Vol. 9. ISSN: 16956141.

- 8. Ciudad Autónoma de Buenos Aires. Ley 1540 Control de la Contaminación Acústica. Decreto Reglamentario Nº740. Buenos Aires: Boletín Oficial Nº211, Expediente Nº54.054/06, 2007.

- 9. IRAM 3801. Sistema de Gestión de Seguridad y Salud Ocupacional. Buenos Aires, Argentina. 1998.

- 10. Tregenza, Tim. Un acercamiento gradual al problema del ruido en el trabajo. Luxemburgo: Agencia Europea para la seguridad y la Salud en el Trabajo, 2005. ISSN: 16084152.

- 11. Monroy, Manuel Martín. Manual del Ruido. Las Palmas de Gran Canaria: Ayuntamiento de Las Palmas de Gran Canaria, 2006. ISBN: 84690055X.

- 12. Ochoa Pérez, Juan M. y Bolaños, Fernando. Medida y Control del Ruido. Barcelona, España: Marcombo S.A., 1990. ISBN: 8426707947.

- 13. Comisión Nacional del Medio Ambiente. Ecomabi. Fundación para la conservación y manejo sustentable de la Biodiversidad. [En línea] 2000. [Citado el: 21 de Noviembre de 2013.] http://www.ecomabi.cl/biblioteca/category/32guiasymanuales.

- 14. Demers, Paul y Teschke, Kay. Capítulo 71: Industria de la Madera. [aut. libro] Organización Internacional del Trabajo. Enciclopedia de la OIT Volúmen III. España: INSHT, 2001.

Papers relacionados