Introduction

The costs of accidents at work and professionals diseases are difficult to quantify accurately, both for companies and for the State. From an economic point of view, an accident at work or a professional disease is not limited to the costs of medical treatment. Have a multiple impact within the company, to the extent that is reflected in direct and indirect costs. Naturally these costs will be more pronounced as smaller is the company. By this fact, when is an investment in measures in order to reduce or eliminate risks, the employer expects a return resulting in job satisfaction, as in the reduction of operating costs [11].

According to the Health General Direction [7], overloading with work during a short period of time or small overloads during a long period of time, as well as the bending, twisting, static positions or repetitive movements can influence directly the appearance of muscle pains and discomforts, which constitute a set of inflammatory and degenerative diseases of the locomotor system.

Sometimes, it is difficult to determine the beginning of a work-related disease, as there are some of those diseases that may take some time to manifest themselves and others that only appear after the employee leave is activity. In this way, the characterization of the relationship between exposure to certain conditions of work and the emergence of the disease is not always easy to do. In addition, there are non-physical factors that trigger this type of diseases. In other words, in its origin may be psychological function problems [10] and this lack of visible signs of disease favors both the ignorance as a superficial approach of the problem [4].

This work has a main objective to analyze the problem of musculoskeletal injuries in the metalworking sector and the associated risks, in particular in the industry of moulds for plastic injection. This study focus is on companies in the region of Marinha Grande.

This way it is proposed to contribute to the knowledge of the most frequent injuries in this industrial sector and reflect on preventive measures that can be adopted. In the same way, investment in healthier workplaces and designed for the people that actually work in this workplaces, reveals a measure to be crucial to the workers health [7]. In fact, although the handling of heavy loads, repetitive motions or unexpected and, yet, the use of force are at the origin of injury to musculoskeletal system, incorrect postures, working environment and psychosocial factors may also accentuate this type of symptomatology.

For its part, the Health and Safety at Work (HSW) complements the whole investigation and contribute with legislation, with the risk assessment, with recommendations and the implementation of corrective actions aimed at improving the work conditions. We looking this way for reducing or eliminating risk in the provision of labor and the reduction of accidents, ensuring healthy workplaces [1].

The moulds industry is one of the most recognized portuguese economic sectors internationally, not only through its strong internationalization, but also, by the fact of being an activity characterized by cutting-edge technology and quality products. Entrepreneurs in the industry have known to respond to daily challenges with innovation, professionalism, competitive prices and strict compliance with the deadlines agreed with the client. They also so offer a permanent monitoring of the downstream amount since the conception process until mold certification and bet on a constant technological development.

Methodology

Research Issue and objective

Already exist extensive literature in Portugal about musculoskeletal injuries in varied activities and sectors, both industrial and services. In particular those studies conducted with nursing professionals, doctors, athletes, musicians, seamstresses, breakers, among many others. However, although we have researched in detail the open access Scientific Repository of Portugal, the Scientific Electronic Library Online (Scielo Portugal) and other online libraries, couldn't identify any research about musculoskeletal injuries in the industry of moulds.

Occupational health professionals that fill the worker's fitness certificate, to indicate if the worker is fit, fit with restrictions or unfit, conditionally should be more committed, more attentive and sensibly workers and the organization with better diagnostics more target for each type of activity, promoting early detection of this type of limiting injuries that the worker can develop.

One of the most important justifications for this work was the fact that the researcher mingle daily with people who suffer from this kind of injury and have realized, that they don't realize that their injuries are derived from their occupational activities, justifying them often with age, although acknowledging that the execution of certain tasks they are painful. Investigation about Repetitive Strain Injuries (RSI), is not an easy task. While, when it is an accident is an event visible and easily recognized as such in society, the work-related musculoskeletal injury may go unnoticed due to lack of indication visible and that take longer to become notorious. The musculoskeletal injury requires tests, reports, and the study of tasks and complicates the employment relationship, between patients with the employer and with the notification system itself [3].

Although the study has with a explorative character fundamentally, the literature review allowed us to advance three possibilities: H1 – there are differences with statistical significance between the symptoms of RSI and the age of the worker; H2 – there is a positive association between body mass index and frequency of symptoms; H3 – there are differences with statistical significance between the worker's age and frequency of pain perceived.

Another additional aspect and in order to ascertain possible situations of risk to the health of these workers, characterized the work environment in which are done the functions relating to production of moulds, in particular regarding the risks to which they are subject; tried to meet for training provided to these workers in the area of health and safety at work, if they have knowledge of the safety regulations of the company, use of personal protective equipment, if they had training to use them properly, which workloads to which they are subject and the most frequent body postures during their working days.

Moulds

As a worldwide supplier, this Portuguese sector occupies the eighth place. The increased demand comes from the automotive industry with 72%, from the household appliance industry with 6% and packaging industry with 5%. The moulds industry represents 0,9% of Portuguese companies, 1,1% of employment and 0,7% of national production, as well as 1,3% manufacturing industry [2].

At the same time, this promoted the installation of steel companies and companies specializing in various stages of manufacture of moulds: design, milling, polishing, prototyping, machinery and equipment, specialized accessories, developing programs, raw materials and dyes, among many others. Has also been significant involvement of Portuguese and foreign universities in the sector, in particular the University of Minho, in Portugal, and the MIT-Massachusetts Institute of Technology, the United States of America.

The main risk factors of Musculoskeletal Injuries

The complaints linked to levels of discomfort, swelling, inflammation, disabilities to perform certain movements, fatigue, decline of professional performance and annoyance are the basis of the evaluation of musculoskeletal injuries connected with the work. The studies point out several factors for the appearance of these injuries. Some of this factors are of ergonomic nature (such as the application of excessive force, much repetition of movements, incorrect and static postures), others (such as cold, heat, noise, vibrations and brightness), other organizations (such as excessive overtime, the absence of pauses, the shift work) and other psychosocial relations.

[16], in the research was carried out, was found that the majority of respondents (61,8%) were overweight or obese. In many of these cases was an intense low back pain (53,5%), indicating that a higher Body mass index is associated with this type of back pain.

Based on data from [6], the physical, chemical, biological risks, the function and the workplace, as well as the associated with equipment and cargo handling, are fundamentally linked to industrial sectors and are those who contribute the most to the emergence of occupational diseases and accidents at work. On the other hand, the ergonomic risks are more prevalent in areas such of information technologies and services. According to the evaluation survey of working conditions, 44,5% of complaints associated with the ergonomic risks refer to physical efforts, and 20,5% are related to stressful and painful postures for long periods of time and 18,9% linked to the performance of repetitive tasks.

Organizational risks tend to appear in less flexible work environments, with precarious labor contracts. The number of working hours, shifts, night work, weekend work and overtime are related to risk factors associated with the working time. The personal and individual psychosocial risks are more difficult to limit and determinate. There is a lack of national information, only the records of occupational diseases and accidents are the sources of information available to us, being insufficient, since it does not explain the factors of labor who were in their origin [6].

Characterization of the sample

As Fortin said [9], "the population comprises all elements (people, groups, objects) which share common characteristics, which are defined by criteria established for the study". A sample is described as "a subset of elements or subjects taken from the population that are invited to participate in the study”.

In this investigation was defined, initially, the population where the study will be conducted. The criterion for its definition were as follows:

- Employees of companies listed in the National Association of Mould Industry, CEFAMOL;

- Companies based in Marinha Grande;

- Employees of companies of moulds, plastic injection (excludes, therefore, companies of moulds for glass and/or ceramic, Foundry mold injected, mold texturing, among others).

Were 29 companies contacted. Of these, only nine have agreed to collaborate in this study. All of them are located in the municipality of Marinha Grande. The elements collected relate to the year preceding the study (2010).

After these companies accept to participate by enterprises, there was a need to confirm the Economic Activity Code in order to confirm the number of employees at December 31, 2010. The sample surveyed was complete for convenience and the questionnaires were delivered and collected between September 1, 2011 and February 10, 2012. The sampled companies are nine, as already mentioned, for a total of 384 employees.

The questionnaires were mostly filled in our presence.

Of the 276 questionnaires collected, were treated 196 of them, the others don’t meet the requirements for inclusion in this study. Having been excluded all workers of administrative, commercial and drawing areas.

Measuring instrument

In this section you present material used for collecting information which formed the base for the present study. Employee questionnaire was adapted from a dissertation written in the specialty of ergonomics in the workplace safety [5], based on Kuorinka and Forcie questionnaire [12]. Was requested and obtained permission from Dr. Filipa de Carvalho, as well as the permission of Professor Florentino Serranheira for the use of demographic characterization issues taken from your method OWAS [17].

With intention of testing the questionnaire proposed by Carvalho [5], which made slight adjustments accepted by the author. The instrument is divided in three sections.

First - General data - contains issues aimed for demographic characterization of the sample. This section includes items for identification of gender, marital status, age, education, weight, height, age and physical activity practice, among others.

Second – health – aims to collect data on the health of respondents, in particular, with regard to symptoms of musculoskeletal injuries, its location, and the frequency of pain, work-related accidents suffered and lost working days.

And the third – the workplace – includes items of assessment of the work environment (lighting, noise, temperature, among others), utilization habits of personal protective equipment, work routines (repetitiveness of tasks, breaks, timetables and postures in task execution) and formation/information in the area of safety, hygiene and health at work.

On the issues that is necessary the use of a scale, was always used the five-point scale of Likert. This range is between 1 "never" and 5 "always"; in questions that concern to the work environment it varies between 1 "very poor" and 5 "very good". In order to ascertain the reliability of the measuring instruments which predispose to the analysis of internal consistency, proceeded to the calculation of the coefficients Kuder-Richardson 20 (KR-20), since this is before qualifying evaluations scales dichotomous (present/absent) and alpha (α) of Cronbach´s for the Likert scales of measure.

After collecting the questionnaires it was created a database in SPSS, Statistical Package for Social Sciences 20, to Windows operating system, program that was used for statistical analysis.

Results and Discussion

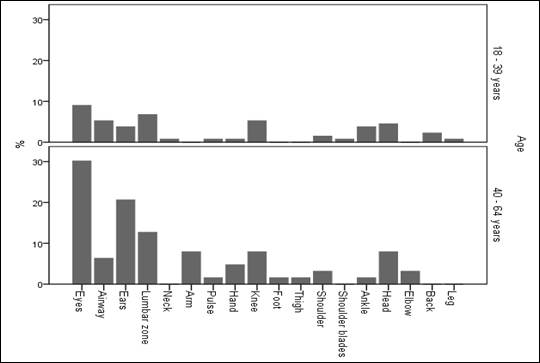

The presence of symptoms or musculoskeletal injuries checked out in the last 12 months is greater in the lumbar area, following up on knees, ankles and arms. On the other hand, the lower incidence areas are related to the shoulder blades, thigh, legs and feet. The arms, hands, and shoulders are in a middle position. However, it is to show that the most frequent complaints are in eyes and ears. The percentages of affirmative responses are represented in two age brackets for function we incorporated: younger employees (from 18 to 39 years) and older workers (aged 40 to 64 years, inclusive). In General, the percentages are higher in class of older workers.

Figure1. The presence of symptoms or work-related musculoskeletal injury in the last 12 months: Percentages depending on the age group.

When inquired about whether respondents suffered some sort of accident at work in the previous year (i, 2010), it was found that, of the 196 respondents, 12,3% responded affirmatively, and of these, 7,2% are the youngest group (18 to 39 years) and 5,1% constitute the older group (from 40 to 64 years).

For those who responded affirmatively at the question about work-related accidents last year, wondered, then, how many days were without work. Verify registers a minimum of five days and a maximum of 270 days. The average score stood at 52,52 days and the standard deviation of 75,13 days.

When was analyzed the number of sick days as a function of these two categories to the age bracket, it was clear that younger respondents gave an average score of 31,38 days (SD = 50.17), while those with more average age was in the 80 days (SD = 94.63). However, the effective difference is only meaningful if we consider the threshold of statistical significance of p = .09. The non-parametric equivalent of the Student t test for independent samples, the Mann-Whitney U, presented a U = 37.50, z = -1.71, p = .088. The relationship with the Body Mass Index (BMI) was also significant, r =-.102, p = .645.

Univariate tests were inspected in order to evaluate differences in age group for each part of the human body taken individually, shows us that only are significant differences between older and newer ones is in respect to the ears, the lumbar zone, arm, elbow and leg. The mean scores show to us that as older are the participants as most have a higher frequency of symptoms or musculoskeletal injuries in these areas, confirming our hypothesis H1 that there are differences with statistical significance between the prevalence of RSI and the age of workers. The analysis of multivariate test due the realization of the MANOVA indicates that the overall effect is statistically significant, Λ of Wilks = 0.823, F (18, 174) = 2.24, p = .005, η2 = .177, indicating that, in general, there are differences in terms of frequency of pain among younger participants and older people.

Calculating of the Pearson correlation coefficients between the frequency of symptoms and BMI did not indicate the existence of any significant relationship, Pearson's correlation coefficients of r =-.095 r = .040, p > .180. These numbers do not allow us to confirm the hypothesis 2, that there is a positive association between BMI and frequency of symptoms.

It was repeated the MANOVA taking as variable independent (VI) the answer to the question whether exercises some kind of physical activity on a regular basis. The overall effect obtained was not statistically significant, Λ of Wilks = 0.910, F (17, 176) = 1.02, p = .440, η2 = .090. However, the analysis of the results of the univariate tests points to statistically significant differences for the frequency of symptoms or musculoskeletal injury in the last 12 months in the lower back, knees and shoulders. Interestingly, the ones that have physical activity on a regular basis show a higher frequency of injuries in these areas.

The repetition of the MANOVA, keeping as VI, the age bracket and considering, now, as dependent variable (DV) frequency of pain in musculoskeletal regions indicated, points again to a statistically significant overall effect, Λ of Wilks = 0.835, F (18, 174) = 1.91, p = 0.018, η2 = .165, where we can concluded that, globally speaking, older participants differ in terms of frequency of pain, which is steeper than in younger participants. These data allowed us to confirm hypothesis 3, that there are differences with statistical significance between the age the frequency of perceived pain.

Concluded that there are differences with statistical significance among younger workers and the elderly ones, such as the pain in the shoulders and neck, muscle fatigue, tingling, blurred vision, temporary deafness and blurred vision, with values more pronounced in older age groups.

In respect the analysis of workplace indicator, in the inquiry administered, has mentioned that the working environment is essential to feel comfortable. It was explained that the fact that there is low light or too much light, excess or absence of noise, temperature extremes (very low or very high), working with equipment or machines vibration stations, as well as the relationship with the leadership, are factors that can reflect the individual well-being. The results of the overall mean scores in ascending order demonstrated that, what disturbs more workers is the noise, followed by air quality and temperature.

When was wondered to respondents if they use personal protective equipment (PPE) in the fulfilment of its tasks. It was found that, of 105 participants, 56% responded affirmatively, while 44% respond negatively. The Chi-square test (χ2) indicated that whoever uses the EPI feels less need to use another type of equipment, compared to those who do not use EPI, χ2 (1) = 34.41, p < .001.

As for breaks and repetitiveness of work it was found that of the 195 valid responses, 57,1% responded affirmatively, while 42,3% responded negatively. The pauses between one and five a day, being the M = 1.672 and SD = 0.70 breaks per day. It was also asked if whether there is repetitiveness of tasks. Of the 190 responses, responded affirmatively 57,9% and 42,1% negatively.

To the question, if “you have already attended training/information actions under SHHW – safety, hygiene and health at work“ – of 123 participants, it was found that 63% gave positive response and 36 percent negative response. Those who answer positively, had awareness training for the use of SHHW, and it was present at most of the training/information, followed by the manual handling of loads

When was asked whether the employees were aware of the safety regulations in force in the company. Of the 186 responses obtained, were 87,1% affirmative and negative responses of participants 12,9%. We decided to cross the info on the presence of training/information initiatives within the framework of the knowledge of SHST safety regulations in force in the company the result of Chi-square test showed us a value of χ2 (1) = 18.17, p < .001, it was found that respondents who attended training/information initiatives within the framework of those who are more SHST show he is aware of the safety regulations in use in the company.

The question "how many hours on average per day working for the company" was answered through 4 options: 8, 9, 10 and more than 10 hours. We found that 33,7% participants indicate work 8h, 21,4% working 9h, 31,6% working 10h and 12,8% over 10 hours daily.

With the presentation of the results with the classification of positions of the participants, according to the execution of their daily tasks in the workplace, it was found that the most common posture is the standing position, followed by leaning forward and back upright postures. Regarding the lifting of loads or use of force we have found equal to average weights of less than 10 kg and weights between 10 and 20 Kg.

Conclusions

This investigation ended, as main goal, to know more deeply the musculoskeletal injuries and work-related risks in the industry of moulds of Marinha Grande. Being the RSI the focus of this investigation, especially as regards the degree of impact on workers of our sample, we didn't want to help but evaluate also other factors influencing the State of health of workers surveyed. In this sense, investigated the factors related to the work environment and exposure to risk, in order to look for other causes that could be adjacent to worst levels of health of these workers, and thus be able to formulate suggestions for improvement of the local and broader working conditions. Despite the exploratory character of this dissertation and conscious of the limitations of this study, it was not possible to have, however, failed to mention that we are in face of the first initiative, academic scope, which assesses the problem of musculoskeletal injuries in this sector of activity.

Regarding the hypotheses formulated initially and on the results obtained, it was noted that, in relation to H1, there are statistically significant differences between the frequencies of symptoms of RSI submitted with the advancement of age of workers. It was found that there is no association between BMI and the frequency of symptoms, and can confirm the H2. The H3 was confirmed, to the extent that the frequency of pain is felt in older workers.

As main conclusions of this research, we began by giving emphasis to the workplace where workers operate our sample, which is characterized by intense and constant noise, as well as by temperature depending on the seasons (cold in the winter, too hot in summer) and poor air quality.

Within the RSI showed that the pain in the lower back, knees, ankles and arms are the most present complaints, although the most frequent were the areas not included properly in the RSI, as is the case of sore eyes and ears.

It is our conclusion that most workers informed about the standards of behavior at work acquire SHHW guided by greater care and attention to situations of risk to their health. This fact is of utmost importance when we talk of younger workers and therefore more prone to accidents at work that may make their lives permanently. Being in the younger workers that falls the continuity of this productive activity, in particular for reasons of retirement of older, additional effort is required to provide training/information to younger people, seeking to raise awareness of the risks inherent in them their professional activity and minimize the number and severity of accidents at work.

Also the fact that, in our sample, a considerable group of workers take breaks during the workday (except the pause for the meal) is another aspect that deserves particular attention. As we know, short breaks during the work are of great importance, especially when it comes to a professional activity that requires physical effort; not just because the breaks allow the muscle relaxation for workers, but also because it gives them the opportunity to carry out any appropriate physical activity, for example, have a gymnastics program appropriate to each type of task, such as some exercises that contradict and correct postures and movements in his labor activity, taking into account the limitations of each worker, albeit slight. Additionally it is also a good occasion to sit a bit, trying to relieve the fatigue of the muscles of the legs and the injury from the working position of foot and inclined forward.

With regard to the registration of accidents at work, the highest percentage of cases fell on younger workers. Also it was found that, in terms of the performance of their duties, most workers perform repetitive character tasks. Being that these workers fit workload of nine or more hours a day, we found that, with the exception of breaks for meals, almost half of the sample makes no breaks during the workday. This situation is of utmost importance when working postures these workers frequently are standing and/or inclined forward and, with some frequency; lift loads weighing up to 20 kg.

Recommendations

In this sense, we recommend daily use of suitable equipment allowing hearing protection in the long term; minimize the damage related to workers audition. We recommend also other protective measures of the health of these workers, such as the installation of equipment to keep the temperature stable environment throughout the year and filters that allow the improvement of air quality. With the implementation of these measures it is expected that, in older age and after a lifetime of working in the production area of this sector of activity, workers may enjoy better health, mainly in terms of bone and lung.

It is imperative that companies invest more in training/information of your employees about SHHW in order to sensitize them to the importance of preserving their health during the period of their lives characterized by productive activity and to the harmful effects that can result from neglect certain risk factors, whose reflexes are more evident in older age.

As regards the repetitive nature of the functions performed by our respondents would be recommended that, whenever possible, companies should develop a system of rotation of tasks between different operators sections, which allowed the same repetitive task for periods not exceeding four hours daily. To this end, we advocate multi-skilling of workers who, in addition to enabling other enterprises, capital gains would also have a minimizer effect of the RSI associated with repetitive work.

With regard to the results obtained, we considered pertinent to be strongly encouraged the use of PPE in order to minimize eye and auditory damage of these workers. The ergonomic workplace adjustment to the characteristics of workers, in particular, those relating to the stature of these, is another aspect that deserves full attention by companies, to reduce RSI that entail. Given the characteristics of standardized dimensions of the machines and the impossibility of them change the architecture in order to adjust its dimensions to the stature of each worker, it is proposed that, where the workplace so permits, the Assembly of small hydraulic loading ramp in order to adapt the machine to the operator's height.

It is recommended that, whenever possible, be isolated machines that promote more noise so that the latter is not unnecessarily imposed on all workers.

Clue for future research

Future studies should involve more objective data resulting from measurements and observations more stringent. Moreover, only through longitudinal studies it will be possible to realize clearly work-related factors that are at the origin of the RSI[14].

Despite some limitations, this study allowed us to deepen the knowledge about the prevalence and incidence of musculoskeletal injuries and risk agents in the sector of activity of molds. We believe that this introductory work about the industry of moulds will serve as leverage for others will be carried out in this sector. It was noted that with regard to working conditions, makes this investigation raise clues to other empirical investigations: noise assessment and analysis of air quality in this industry. Under the designation of RSI, we found a set of inflammatory and degenerative diseases of the locomotor system which are the result of the subjection of the worker to various occupational risks such as posture, the repetitiveness of tasks or the overhead [15].

The ergonomic adjustment of workplaces physical characteristics of workers are, whenever possible, also recommended. We believe that the implementation of these recommendations will promote the improvement of these work environments, as well as the health and safety of workers in this industry.

There is, in fact, a consensus among the authors by saying that these are pathologies of multifactorial character, involving aspects of individual order, physics and organization of work [11]; [; [13]; [17] the personal and organizational consequences that imply, the RSI should be the target of a holistic approach. The development of methods of prevention and employee training and information can contribute to meet new procedures that protect your health [8]. Only with in-depth contribution from various disciplines will be possible to define the most appropriate organizational interventions, both to prevent the onset of RSI and to reduce the impact they have on workers ' life and the results of its performance [18].

Despite the limitations encountered, we hope and we wish that our study will contribute to the improvement of working conditions and safety of mold industry workers of Marinha Grande, as well as all those who, somehow, may be subject to similar working conditions. The suggestions for improvement that we intend to give an adequate response to the problems identified and to promote risk reduction and the occurrence of RSI; on the other hand, aim to improve the efficiency and productivity of enterprises. As we have seen, the RSI constitute as a factor limiting the productive activity of enterprises through prolonged periods of removal of workers from workplaces, required for the (eventual) recovery of your health. Now, to promote healthier working conditions, we expect to reduce absenteeism of workers favoring thus the productivity of companies and, consequently, their profitability. Took care to propose inexpensive solutions in the sense of these not being excessively onerous for businesses and discourage its implementation soon departure.

Acknowledgments

A preliminary version of this paper has been presented at ORPconference 2014.

Everyone who believed in me and made this work possible.

The Embalnor group (“Embalnor, packaging, S.A.”, “Famopla, Portuguese Manufactures Plastic Moulds, Lda” and “Freddom to Enjoy”) that helped me to came to ORP2014.

Special thanks to my professor PhD Miguel Corticeiro Neves and also to the entire organization of ORP2014.

References

- 1. Agência Europeia para a Segurança e Saúde no Trabalho, (2009). Locais de trabalho seguros e saudáveis. Bom para si, bom para as empresas. Campanha Europeia sobre a avaliação de riscos. Belgium: Agência Europeia para a Segurança e Saúde no Trabalho (OSHA).

- 2. Agência para o Investimento e Comércio Externo de Portugal, (2011). Portugal: Perfil País. Lisboa: AICEP Portugal Global.

- 3. Assunção, A., & Vilela, L. (2009). Lesões por esforços repetitivos: Guia para profissionais de saúde. Belo Horizonte: Editora Verónica Cavaliere.

- 4. Augusto, V., Sampaio, R., Tirado, M., Mancini, M., & Parreira, V. (2008). Um olhar sobre as LER/DORT no contexto clínico do fisioterapeuta. Revista Brasileira de Fisioterapia, 12 (1), 4956.

- 5. Carvalho, F. (2007). Avaliação de risco: Estudo comparativo em diferentes métodos de avaliação de risco em situação real de trabalho. Cruz Quebrada: Faculdade de Motricidade Humana, tese disponível para consulta na Biblioteca FMH – Tese M 1557 e Tese M 1558.

- 6. Centro de Reabilitação Profissional de Gaia, (2005). Acidentes de trabalho e doenças profissionais em Portugal. Riscos profissionais: Factores e desafios. Arcozelo: CRPG.

- 7. Direcção Geral da Saúde. (2008). Lesões músculo esqueléticas relacionadas com o trabalho: Guia de orientação para a prevenção. Lisboa: Direcção Geral Ministério da Saúde. Acedido em 23 de maio, 2011, em http://www.portaldasaude.pt/NR/rdonlyres/ A0E84C50754C4F859DA597084428954E/0/lesoesmusculoesqueleticas.pdf

- 8. Figueira, B. (2011). Associação dos Factores Ocupacionais com a Prevalência de Lesões MúsculoEsqueléticas Relacionadas com o Trabalho numa Fabrica de Industria Automóvel. Dissertação de Mestrado da Universidade Técnica de Lisboa.

- 9. Fortin, M. (2009). O processo de investigação: Da concepção à realização. Loures: Lusociências Edições Técnicas e Científicas.

- 10. Freitas, L. (2003). Gestão da segurança e saúde no trabalho. Edições Universitárias Lusófonas.

- 11. Freitas, L. (2004). Gestão da segurança e saúde no trabalho. Edições Universitárias Lusófonas.

- 12. Kuorinka, I., & Forcier, L. (1995). Work related musculoskeletal disorders: A reference book for prevention. London: Taylor & Francis (Eds.).

- 13. Martins, J. (2008). Percepção do risco de desenvolvimento de lesões músculoesqueléticas em atividades de enfermagem. Dissertação de Mestrado em Engenharia Humana. Universidade do Minho.

- 14. Punnett, L., & Wegman, D. (2004). Workrelated musculoskeletal disorders: the epidemiologic evidence and the debate. Journal of Electromyography and Kinesiology, 14(1), 1323.

- 15. Queiroz, M., Uva, A., Carnide, F., Serranheira, F., Miranda, L., & Lopes, M. (2008). Lesões Músculoesqueléticas Relacionadas com o Trabalho. Guia de Orientação para a Prevenção. Ministério da Saúde. Direcção Geral de Saúde. Programa Nacional para as Doenças Reumáticas. Lisboa: DGS.

- 16. Salvetti, M. (2010). Incapacidade em pessoas com dor lombar cronica: Prevalência de factores preditivos. São Paulo: Universidade de São Paulo.

- 17. Serranheira, F. (2007). Lesões esqueléticas ligadas ao trabalho: Que métodos de avaliação de risco? Tese de Doutoramento em Saúde Publica. Lisboa: Universidade Nova de Lisboa.

- 18. Silverstein, B., & Clark, R. (2004). Interventions to reduce workrelated musculoskeletal disorders. Journal of Electromyography and Kinesiology, 14(1), 135152.

Papers relacionados