Schaub, Karlheinz

Institute of Ergonomics / Darmstadt University of Technology (IAD) / Petersenstr. 30 / D-64287 Darmstadt, Germany+49 (0) 6151 16 3489 / schaub@iad.tu-darmstadt.deWakula, Jurij; Berg, Knut; Bruder, RalphInstitute of Ergonomics / Darmstadt University of Technology / Petersenstr. 30 / D-64287 Darmstadt, Germany+49 (0) 6151 16 2987 / sek@iad.tu-darmstadt.deGlitsch, Ulrich; Ellegast, Rolf-PeterInstitute for Occupational Safety and Health of the German Social Acci- dent Insurance (IFA) /Alte Heerstr. 111 / 53757 Sankt Augustin, Germany+49 (0) 22 41 2 31 02 / ifa@dguv.de

ABSTRACT

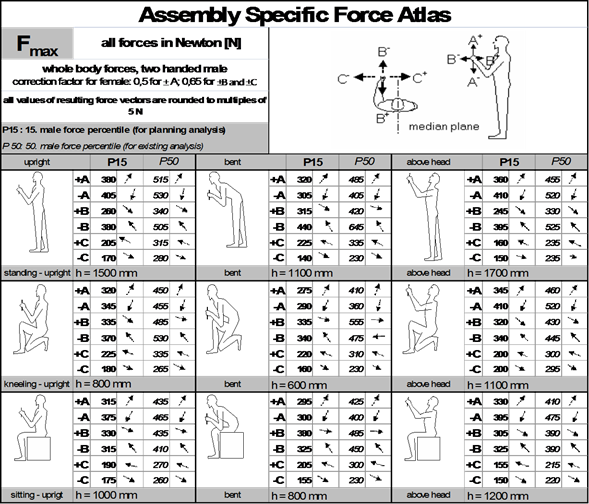

Though working in hi-tech industries, physical workload is partly considerable and can- not be avoided due to product and process requirements. Especially in automotive, aviation and marine industries, the assembly of the product geometry requires force exertions in ergonomically unfavorable conditions. Unfortunately internationally ac- cepted methods for the evaluation of those force exertions are widely unknown. Be- sides some traditional German methods and EN 1005-3 hardly any evaluation methods exist. And even those methods refer to force exertions in primarily upright symmetric working postures. In order to overcome these problems the ―Assembly Specific Fore Atlas‖ was created during the recent years. From a sample of automotive workers (n=273) a set of 54 whole body forces (6 main force directions while standing, sitting, kneeling; in an upward, bent and overhead posture) and a set of 38 types of finger- hand forces (all at MWC value) were measured in the field. The inputs for the types of force exertions required in practice were sampled from a consortium of major Euro- pean car and truck companies. In addition, evaluation methods were developed that allow calculating maximum recommended force limits from the measured maximum static forces and task and user group relevant parameters. These methods were de- signed in a traditional as well as screening approach with respect to existing interna- tional examples. This contribution gives a short overview on the data collected and focuses on the evaluation methods realized and the results drawn from the first field tests.

Keywords

Force exertions, EU legal requirements, automotive industries

INTRODUCTION

Ergonomically designed work systems enhance safety, improve human working and living conditions and counteract adverse effects on human health. Also they usual- ly improve the operator-machine system performance and reliability. Applying ergo- nomics to the design of work systems, especially where the design of machinery is concerned, ensures that human capabilities, skills, limitations and needs are taken into account. [6]

High physical workload is nevertheless also present in hi-tech industries, if the geometry of the product requires force exertions in ergonomically unfavorable condi- tions. This is the case especially in automotive, aviation and marine industries.

Unfortunately internationally accepted methods for the evaluation of those force exertions are widely unknown. Besides some traditional German methods [5, 7] and EN 1005-3 [2, 3] hardly any evaluation methods exist. And even those methods refer to force exertions in primarily upright symmetric working postures.

To overcome these problems, an ―Automotive Force Atlas‖ for symmetric whole body forces was realized in cooperation with a big German car manufacturer in the German Rhine-Main area [16].

Soon the need for force exertions in asymmetric postures, one handed opera- tion, etc. emerged. The idea for an ―Assembly Specific Force Atlas‖ emerged.

HISTORY AND PROJECT CONSORTIUM

In 2004 a project group for an ―Assembly Specific Force Atlas‖ was founded. It consisted primarily from partners from vehicle and truck industries. They were sup- ported by companies form the aviation sector. Recently interests emerged from the ship industry to work on a ―marine‖ supplement of the atlas.

Financial support was given from the German Social Accident Insurance (DGUV). The scientific part was worked out by the IAD (Institute of Ergonomics, Darmstadt University of Technology) supported by the Institute for Occupational Safety and Health of the German Social Accident Insurance (IFA). Additional support was giv- en from the Federal Institute for Occupational Safety and Health (BAuA) as a govern- mental research institution. The partners of the consortium are shown in fig. 1.

Figure 1: Consortium of the Assembly Specific Force Atlas

|

|

Project-Consortium

Institut für Arbeitswissenschaft Technische Universität Darmstadt |

METHODS

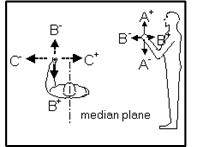

Figure 2: Force directions

A matrix of different real type working postures was elaborated within the consortium and practioneers from the companies were asked for the practical relevance of the different types of force exertions. The result is shown in fig. 3. Fig. 2 gives an overview on the various force directions as defined in DIN 33411-1 [4] and refe- renced in fig. 3.

Figure 3: Practical relevance of different types of force exertions

|

Trunk |

Trunk |

Trunk |

|||||||||||||||

|

upright |

twisted |

lateral bent |

t & lat. ben |

upright |

twisted |

lateral bent |

t & lat. ben |

upright |

twisted |

lateral bent |

t & lat. ben |

||||||

|

A+: |

31 |

14 |

10 |

9 |

A+: |

33 |

12 |

12 |

9 |

A+: |

35 |

22 |

14 |

14 |

|||

|

A-: |

29 |

16 |

11 |

10 |

A-: |

40 |

19 |

18 |

15 |

A-: |

22 |

5 |

3 |

3 |

|||

|

B+: |

32 |

15 |

11 |

10 |

B+: |

36 |

14 |

13 |

10 |

B+: |

20 |

7 |

4 |

4 |

|||

|

B-: |

33 |

16 |

11 |

11 |

B-: |

40 |

19 |

14 |

12 |

B-: |

30 |

17 |

9 |

9 |

|||

|

C+: |

26 |

13 |

9 |

8 |

C+: |

33 |

12 |

12 |

9 |

C+: |

25 |

12 |

7 |

7 |

|||

|

C-: |

26 |

13 |

9 |

8 |

C-: |

33 |

12 |

12 |

9 |

C-: |

26 |

13 |

8 |

8 |

|||

|

standing upright |

standing bent |

standing above head |

|||||||||||||||

|

A+: |

8 |

4 |

3 |

2 |

A+: |

2 |

2 |

2 |

1 |

A+: |

6 |

6 |

2 |

1 |

|||

|

A-: |

8 |

4 |

3 |

2 |

A-: |

6 |

6 |

6 |

5 |

A-: |

2 |

2 |

1 |

0 |

|||

|

B+: |

8 |

3 |

2 |

1 |

B+: |

2 |

1 |

1 |

0 |

B+: |

1 |

1 |

1 |

0 |

|||

|

B-: |

8 |

4 |

3 |

2 |

B-: |

6 |

6 |

6 |

5 |

B-: |

6 |

6 |

2 |

1 |

|||

|

C+: |

8 |

4 |

3 |

2 |

C+: |

4 |

4 |

4 |

3 |

C+: |

2 |

2 |

1 |

0 |

|||

|

C-: |

8 |

3 |

2 |

1 |

C-: |

4 |

3 |

3 |

2 |

C-: |

1 |

1 |

1 |

0 |

|||

|

crouching upright |

crouching bent |

couching above head |

|||||||||||||||

|

A+: |

18 |

6 |

6 |

5 |

A+: |

15 |

5 |

5 |

3 |

A+: |

18 |

9 |

4 |

3 |

|||

|

A-: |

18 |

6 |

6 |

5 |

A-: |

18 |

8 |

8 |

6 |

A-: |

14 |

5 |

4 |

3 |

|||

|

B+: |

17 |

4 |

4 |

3 |

B+: |

14 |

3 |

3 |

1 |

B+: |

13 |

4 |

3 |

2 |

|||

|

B-: |

22 |

10 |

6 |

5 |

B-: |

22 |

12 |

8 |

6 |

B-: |

18 |

9 |

4 |

3 |

|||

|

C+: |

18 |

6 |

6 |

5 |

C+: |

16 |

6 |

6 |

4 |

C+: |

13 |

4 |

3 |

2 |

|||

|

C-: |

18 |

5 |

5 |

4 |

C-: |

16 |

5 |

5 |

3 |

C-: |

13 |

4 |

3 |

2 |

|||

|

kneeling upright |

kneeling bent |

kneeling above head |

|||||||||||||||

|

A+: |

23 |

10 |

9 |

9 |

A+: |

28 |

11 |

10 |

8 |

A+: |

31 |

14 |

10 |

9 |

|||

|

A-: |

23 |

10 |

9 |

9 |

A-: |

28 |

11 |

10 |

8 |

A-: |

23 |

6 |

5 |

4 |

|||

|

B+: |

18 |

5 |

4 |

4 |

B+: |

23 |

6 |

5 |

3 |

B+: |

22 |

5 |

4 |

3 |

|||

|

B-: |

27 |

14 |

9 |

9 |

B-: |

32 |

15 |

10 |

8 |

B-: |

32 |

15 |

11 |

10 |

|||

|

C+: |

23 |

10 |

9 |

9 |

C+: |

28 |

11 |

10 |

8 |

C+: |

28 |

11 |

7 |

6 |

|||

|

C-: |

19 |

6 |

5 |

5 |

C-: |

24 |

7 |

6 |

4 |

C-: |

24 |

7 |

6 |

5 |

|||

|

sitting upright |

sitting bent |

sitting above head |

|||||||||||||||

|

legend: |

|||||||||||||||||

|

20 to 40 = applies frequently |

|||||||||||||||||

|

5 to 19 = applies |

|||||||||||||||||

|

1 to 4 = applies rarely |

|||||||||||||||||

|

0 = does not apply |

|||||||||||||||||

Pre-Tests in the lab revealed that asymmetric trunk positions could hardly be reproduced properly in the field. Another experience from the lab was the fact that kneeling and crouching resulted in similar levels of forces. With respect to the time needed to carry out the force measurements, the decision was made to measure the cases of symmetric standing, kneeling and sitting postures (upright, bent, above head) only (n=54); see also fig. 7. The influence of asymmetric trunk positions and one- handed operations should become a matter of further investigations in the lab.

|

|

The results of the study are described by Wakula et al. [241, 25] |

1 http://www.dguv.de/ifa/de/pub/rep/reports2009/bgia0309/index.jsp http://www.kraftatlas.net/downloads

Data acquisition

Data acquisition took place in the field and in the labs of IFA and IAD. A detailed description of the equipment and techniques used as well as the results gained, can be found by Berg et al. [1] and Wakula et al. [22, 23].

Force measurements in the field

Forces were measured from 273 male workers in 11 plants. The average stature of the subjects was 179±7 cm, the weight 86±13 kg and the age 39±9 years.

From each person a grand total of 108 arm-shoulder / whole body forces and 76 force of the finger-hand-system were collected. The data were statistically elaborated and presented as force percentiles. The results of this study are described by Wakula et al. [24].

Experiments in the IFA and IAD labs

Experiments in the IAD lab with 7 subjects (stature 184,4±4 cm, weight 81,9±9,8 kg, age 28±7,9 years) showed that asymmetric leg & trunk postures had no significant influence on the maximal capacities of the measured action forces. The same applies (dependant from the force direction) to about 20 % of the experiments that compared one-arm vs. two-arm force exertions (see Wakula et al. [26]).

As a consequence of these partly unexpected results two additional studies had been carried out in the IFA lab. One study considered asymmetric vs. symmetric post- ures during force exertions (n=6, stature 181,7±8,1 cm, weight 78,8±8,3 kg, age 39,0±9,1 years, BMI 23,9±2,7 kg/m2). Another study focused onto two-handed vs. one handed operation (n=6, stature 179,8±6,1 cm, weight 79,7±8,1 kg, age 35,5±13,7 years, BMI 24,6±2,0 kg/m2). The studies included next to the force mea- surements a 3D motion analysis and subsequent a biomechanical analysis and evalua- tion. One outcome of these studies was that asymmetric leg or trunk positions did not necessarily result in lower levels of action-forces (forces given from the human body to outside), but required a much higher amount of internal (muscle) forces. Therefore a―Biomechanics-Factor‖ was created that considers the increased muscular load due to asymmetric loads of trunk, legs and arms. As additional muscular load is needed to enter or leave unfavorable postures or to maintains these postures for a longer time while action forces are exerted, a ―Physiology-Factor‖ was created in addition to the―Biomechanics-Factor‖ that considers these increased levels of internal muscle forces. The ―Biomechanics-Factor‖ and the ―Physiology-Factor‖ as a main result of the IFA stu- dies are described by Glitsch et al. [8, 24].

Modeling the force evaluation tools

Evaluation tools for the exertion of action forces have a long tradition in Germa- ny [14].

Similar to those approaches EN 1005-3 [5, 7, 13] and ISO 11228-2 [9, 13] had been modeled.

Whereas traditional German methods focused also on individual characteristics (age, gender and training status), CEN and ISO standards use a more statistical ap-proach and focus on the ―intended user‖ or ―general working‖ populations and their distributions in force capabilities. All approaches calculate a maximum recommended force limits. The ratio of the force to be exerted and the maximum recommended force limit serves a basis for assigning a risk zone according to the 3 zone rating system asdescribed in EN 614-1 [5, 6].

When performing risk assessments at shop floor level according to the EC Framework Directive on health and safety at work [2] and relevant Individual Direc- tives (e.g. on manual material handling [3]) more easily applicable methods are de- sired, in order to keep the effort needed at a considerable level.

To solve the problem for an easy applicable screening tool, the Federal German Institute of Occupational Safety and Health created ―Key Indicator Methods‖ [21] tomeet the EU legal requirements of the Manual Handling Directive [3].

The Assembly Specific Force Atlas picked up both approaches [20] for his eval- uation model as shown in fig. 4.

For the individual characteristics data from Rühmann & Schmidtke [12] and Peebles & Norris [11] had been considered.

The classical approach is realized as described in chapter ―results‖; the screen-ing approach is still being modeled and tested.

Both approaches support a multi tasking in order to meet the requirements for practical applications at shop floor level.

For homogenous force exertion (similar level of the ration of forces exertions and maximal force capacities) the total frequency and the average weighted force le- vels are considered. This approach is comparable to the NIOSH 1981 ―multi-tasking‖ [10].

For inhomogeneous force exertions a second approach was implemented in or-der to avoid the neglecting (middle out) of highly demanding sub tasks. This second approach emulates the NIOSH 1994 [26] and allows to indentify risky force exertions that should be redesigned with respect to the biomechanical load situation. The first approach estimates an average force level, which yields onto the total physical work- load (e.g. energy expenditure).

Whereas homogenous force exertions are suitable for a paper & pencil method, inhomogeneous force exertions need a pc support.

Figure 4: Model of the Assembly Specific Force Atlas’ approach

Forces of the whole body

/ arm-shoulder-system

Forces of fingers / hand

Fmax

Screening

dual related parametersndividual parametersvAge

qIndiviqI

vGendervStatus of training / practiceqStatistical parametersvForce percentile

qTask related parameters

Fmax

Classical approach

qFrequency of operationsqShift duration

RESULTS

The modeling of force evaluation tools resulted in a paper & pencil method for the evaluation of homogenous whole body or finger-hand force exertions. Major ele- ments of the force evaluation method are shown in fig. 5 - 8.

An EXCEL spreadsheet was designed to evaluate homogenous & inhomogeneous force exertions for whole body and finger-hand operations.

For further information refer to the Assembly Specific Force Atlas [24].

Figure 5: paper & pencil worksheet for homogeneous whole body forces

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Appendix D1. Whole body forces – homogeneous tasks

3 Step: Calculate force index FI = Factual / Frec and derive risk level

< 0,85 Green Low risk - recommended; no actions required0,85 – 1,0> 1,0 Yellow Red Possible Risk – not recommended; redesign / actions to lower the risk required High risk – to be avoided; measures to control the risk are requiredlegend

If several types of force exertions occur within the analyzed working period, the total frequency of force exertions and the frequency weighted average force level have to be considered. |

Fig. 6: frequency factors T1

|

frequency per minute |

0 |

0,5 |

0,67 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

frequency per 8h |

240 |

322 |

480 |

960 |

1440 |

1920 |

2400 |

2880 |

3360 |

3840 |

4320 |

4800 |

5280 |

5760 |

|

|

T1 acc. Schultetus (finger-hand forces) |

0,80 |

0,75 |

0,74 |

0,72 |

0,67 |

0,66 |

0,63 |

0,61 |

0,58 |

0,57 |

0,55 |

0,54 |

0,52 |

0,51 |

0,50 |

|

T1 acc. Schultetus (whole body forces) |

0,80 |

0,68 |

0,67 |

0,64 |

0,59 |

0,54 |

0,50 |

0,45 |

0,41 |

0,37 |

0,34 |

0,30 |

0,27 |

0,24 |

0,21 |

|

T1 acc. EN 1005-3; t*) ≤ 3 sec |

0,80 |

0,64 |

0,40 |

||||||||||||

|

*) t = duration of each force exertion |

|||||||||||||||

Fig 7: Isometric whole body forces Fmax

Fig. 8: Isometric finger-hand forces Fmax

|

Assembly Specific Force Atlas |

||||||||||||||||

|

Fmax |

Finger-hand forces male; (correction factor for female values: 0,65) |

|||||||||||||||

|

type of force exertion |

Ø 40 mm

|

|

distance 15mm

|

distance 15mm

|

span 65 mm

|

|

|

span 51 mm

|

||||||||

|

posture |

sitting |

standing |

sitting |

standing |

sitting |

standing |

sitting |

standing |

sitting |

standing |

sitting |

standing |

sitting |

standing |

sitting |

standing |

|

15. percentile |

255 |

230 |

100 |

125 |

80 |

70 |

245 |

175 |

335 |

65 |

85 |

|||||

|

50. percentile |

365 |

340 |

145 |

170 |

105 |

90 |

340 |

260 |

450 |

85 |

115 |

|||||

For further information on the influence of age see Wakula et al. [24]. For de- tails on the biomechanics and physiology factors see Glitsch et al. [8] and Wakula et al. [24].

DISCUSSION

Reactions from industry show that the approach is widely applicable and offers expected evaluation results for most cases.

For complex or prolonged quasi static work situations (e.g. manipulating bigger handling aids for the cockpit or seat assembly) additional guidance must be elaborated for the users. Due to the fairly new development and the new approaches included(e.g. biomechanics and physiology factors), there is still a bigger need for an extended testing of this method in the field and a sharing of experiences gathered in order to extend and improve the applicability of the Assembly Specific Force Atlas.

The Automotive Force Atlas [16] and the Assembly Specific Force Atlas are an integral part of the IAD screening methods on physical workload [17, 18, and 19].

ACKNOWLEDGMENTS

Thanks to all colleagues in BAuA, BGM, IFA, industrial partners and IAD who contributed in the realization of the Assembly Specific Force Atlas.

REFERENCES

- 1. Berg, K. ; Wakula, J. ; Schaub, K.: Isometrische Maximalkräfte des Hand Fingersystems für einen montagespezifischen Kraftatlas. In: Produkt und Produk tionsErgonomieAufgabe für Entwickler und Planer, 54. Arbeitswissenschaftlicher Kongress, 09.04. 11.04.2008 in München, Tagungsband. Dortmund: GfAPress. S. 637 – 640. ISBN 97839368040605

- 2. Council Directive 89/391/EEC of 12 June 1989 on the introduction of measures to encourage improvements in the safety and health of workers at work (Official Journal L 183 , 29/06/1989 P. 0001 – 0008)

- 3. Council Directive 90/269/EEC of 29 May 1990 on the minimum health and safety requirements for the manual handling of loads where there is a risk particularly of back injury to workers (fourth individual Directive within the meaning of Article 16 (1) of Directive 89/391/EEC) (Official Journal L 156 , 21/06/1990 P. 0009 – 0013)

- 4. DIN 334111:1982 Körperkräfte des Menschen; Begriffe, Zusammenhänge, Bes timmungsgrößen (Human physical strength of man; concepts, interrelations, defin ing parameters)

- 5. DIRECTIVE 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast). (Official Journal of the European Union L 157/24. 9.6.2006)

- 6. EN 6141:2006/prA1:2008. Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles.

- 7. EN 10053:2002+A1:2008. Safety of machinery Human physical performance Part 3: Recommended force limits for machinery operation.

- 8. Glitsch, U.; Ellegast, R.; Schaub, K.; Wakula, J.; Berg, K.: Biomechanische Analyse von Ganzkörperkräften in unterschiedlichen Körperhaltungen. In: Produkt und ProduktionsErgonomieAufgabe für Entwickler und Planer, 54. Arbeitswissen schaftlicher Kongress, 09.04. 11.04.2008 in München, Tagungsband. Dortmund: GfAPress. S. 429 – 432. ISBN 97839368040605

- 9. ISO 112282. Ergonomics — Manual handling — Part 2: Pushing and pulling

- 10. National Institute for Occupational Safety and Health (NIOSH), DHHS, Work Prac tices Guide for Manual Lifting. 1981

- 11. Peebles L.; Norris, B.: Filling 'gaps' in strength data for design. Applied Ergonom ics, Volume 34, Number 1, January 2003 , pp. 7388(16)

- 12. Rühmann, H.; Schmidtke, H.: Körperkräfte des Menschen : Perzentilierung isome trischer Maximalkräfte sowie Ausdauer und Beanspruchung bei konzentrischer und exzentrischer Muskelarbeit , in: Rühmann, H.; Schmidtke, H. (Hrsg.): Kolloquium des Lehrstuhls für Ergonomie der Technischen Universität München zum HdA Projekt "Körperkräfte des Menschen Teil II". O. Schmidt, Köln 1992.

- 13. Schaefer, P.; Schaub, K.: Recommended Force Limits for Machinery Operation: A New Approach Reflecting User Group Characteristics. In: Karwowski, W.,.Handbook on Standards and Guidelines in Ergonomics and Human Factors, Mahwah/London 2006, S. 293306. ISBN 0805841296

- 14. Schaub, K.; Landau, K.; Menges, R.; Großmann, K.: A Computer Aided Tool for Ergonomic Workplace Design and Preventive Health Care. In: Human Factors and Ergonomics in Manufacturing, Vol. 7, 4 (1997), p. 269 – 304.

- 15. Schaub, K.; Schaefer, P.: Ergonomics of Manual Handling – Part 2: Pushing and Pulling. In: Karwowski, W.. Handbook on Standards and Guidelines in Ergonomics and Human Factors, Mahwah/London 2006, S. 271291. ISBN 0805841296

- 16. Schaub, K.; Berg, K.: Der automobilspezifische Kraftatlas – Eine Datenquelle zur Bewertung von Aktionskräften in realtypischen Körperhaltungen. (The automotive force atlas – a data source for the evaluation of action forces in realtype working postures.) In: GfAJahresdokumentation 2005 der Gesellschaft für Arbeitswissen schaft e.V. (Hg.), Personalmanagement und Arbeitsgestaltung, Bericht zum 51. Arbeitswissenschaftlichen Kongress an der Universität Heidelberg, 22. – 24. (An nual congress of the German Ergonomics Society). März 2005, Dortmund 2005, S. 479 – 482. ISBN 393680401X

- 17. Schaub, K.; Landau, K.; Bruder, R.: Development and application of methods for stress analysis in manufacturing. In: (CDRom) AHFE International Conference, 2nd International Conference on Applied Human Factors and Ergonomics 2008, Ju ly 1417, 2008, Caesars Palace – Las Vegas, Nevada USA, Louisville (KY) 2008

- 18. Winter, G.; Schaub, K.; Bruder, R.; Landau, K.: The application of the ergonomic screeningtool (AAWS) to support design engineers in product and process devel opment. Physical capabilities and workload for pushing and pulling trolleys aboard aircraft. In: NES 2008 Abstracts, Ergonomics is a lifestyle, 40th Annual Conference of the Nordic Ergonomics Society, Reykjavík, Iceland, August 1113, 2008, p. 191.

- 19. Schaub, K.; Rademacher, H.; Caragno, G.; Guth, A.; Bruder, R.: Ergonomics risk assessments in automotive and electrical industry based on the dual European concept of health and safety at work. In: NES 2008 Abstracts, Ergonomics is a life style, 40th Annual Conference of the Nordic Ergonomics Society, Reykjavík, Icel and, August 1113, 2008, p. 230.

- 20. Schaub, K. ; Berg, K. ; Wakula, J. ; Glitsch, U. ; Ellegast, R. ; Bruder, R.: Entwick lung eines Kraftbewertungsverfahrens im Rahmen des montagespezifischen Kräfteatlas. In: 55. Kongress der Gesellschaft für Arbeitswissenschaft (GfA), 04. 06. März 2009 in Dortmund, Tagungsband. Dortmund: GfAPress. S. 665 – 668. ISBN 9783936804079

- 21. Steinberg, U.; Caffier, G.; Liebers, F.: Assessment of Manual Material Handling based on Key Indicators – German Guidelines. In: Handbook of Standards in Ergo nomics and Human Factors. Ed. by W. Karwowski. Lawrenz Erlbaum Associates. Mahwah, New Jersey, London 2006. S. 319338. ISBN 0805841296

- 22. Wakula, J. ; Berg, K. ; Schaub, K.: Isometrische Maximalkraftwerte für realty pische Kraftausübungen des Arm Schulter und Ganzkörpersystems für einen montagespezifischen Kraftatlas. In: Produkt und ProduktionsErgonomieAufgabe für Entwickler und Planer, 54. Arbeitswissenschaftlicher Kongress, 09.04. 11.04.2008 in München, Tagungsband. Dortmund: GfAPress. S. 423 – 427. ISBN 97839368040605

- 23. Wakula, J.; Berg, K.; Schaub, K.; Bruder, R.; Glitsch, U.; Ellegast, R.: Statistische maximale Ganzkörper und HandFingerkräfte für realtypische Kraftausübungen für den montagespezifischen Kraftatlas. In: 55. Kongress der Gesellschaft für Ar beitswissenschaft (GfA), 04. 06. März 2009 in Dortmund, Tagungsband. Dort mund: GfAPress. S. 455 – 459. ISBN 9783936804079

- 24. Wakula, J.; Berg, K.; Schaub, Kh.; Bruder, R.; Glitsch, U.; Ellegast, R. (2009): Der montagespezifische Kraftatlas. (The assembly specific force atlas) BGIAReport 3 / 2009. Hrsg. von der Deutschen Gesetzlichen Unfallversicherung (DGUV) (Institute for Occupational Safety and Health of the German Social Accident Insurance (IFA)). Berlin: March 2009, Final report. ISBN 9783883837888. ISSN 1869 3491

- 25. Wakula, J.; Berg, K.; Schaub, K.; Bruder, R.; Glitsch, U.; Ellegast, R.: Isometric maximum forces of the wholebody in not upright postures and handfingerforces for the assemblyspecific atlas. In: 17th World Congress on Ergonomics (IEA) 09. 14. August 2009, Beijing (China).

- 26. Waters TR, PutzAnderson V, Garg A, Fine LJ. Revised NIOSH equation for the de sign and evaluation of manual lifting tasks. Ergonomics. 1993 Jul; 36(7):74976.